Leave Your Message

Metal recycling is gaining momentum as we move closer to 2026. Innovations in technology and shifts towards sustainable practices are reshaping the industry. This trend is not just about cost savings; it’s about creating a healthier planet.

In recent years, we’ve seen new techniques emerge. Advanced sorting technologies are improving efficiency. These innovations promise better quality metals for reuse. However, challenges remain. Many facilities still rely on outdated processes. This can hinder overall progress and sustainability.

Sustainable practices are now more critical than ever. Companies are beginning to adopt circular economy principles. Yet, there’s room for improvement. A lack of awareness about metal recycling limits participation. Education can bridge this gap. The future of metal recycling should prioritize both innovation and accessibility.

Metal recycling is evolving rapidly. Emerging technologies are paving new paths for the industry in 2026. Advanced sorting techniques using artificial intelligence enhance the extraction of metals from waste. This process reduces contamination and improves the quality of recycled materials. Robots equipped with AI can identify different types of metals more efficiently than humans.

Hydrometallurgy is gaining attention too. It uses aqueous solutions to extract metals from ores and waste. This method is less harmful to the environment than traditional smelting processes. However, the energy consumption of these methods requires evaluation. Striking a balance between efficiency and sustainability is essential.

Blockchain technology is also surfacing in metal recycling. It offers traceability for recycled materials. Consumers demand transparency in sourcing. Yet, the implementation of blockchain can be challenging. Not all players in the supply chain are ready for this change. Adoption requires collective effort and education within the industry.

| Trend | Description | Emerging Technologies | Sustainability Impact |

|---|---|---|---|

| AI-Driven Sorting | Utilizing artificial intelligence for efficient sorting of metals. | Machine learning algorithms for material recognition. | Increases recycling rates by reducing contamination. |

| Hydrometallurgical Processes | Using aqueous solutions for extracting metals from ores and recyclables. | Advanced leaching techniques and solvent extraction. | Lower environmental footprint compared to traditional smelting. |

| Blockchain for Traceability | Implementing blockchain to enhance traceability in metal recycling. | Decentralized ledger technology for tracking materials. | Improves accountability and reduces illicit trading. |

| Circular Economy Practices | Emphasizing designs that facilitate reuse and recycling. | Product lifecycle assessments and eco-design tools. | Encourages sustainable consumption and waste reduction. |

| Smart Recycling Bins | Implementing sensors and IoT for better collection and sorting. | Connected smart bins with real-time data monitoring. | Optimizes collection routes and improves recycling efficiency. |

The metal recycling industry is undergoing a transformative shift, driven by

sustainable practices. According to a recent report by the

International Metal Recycling Association, the sector could recycle up to

90 million tons of metal globally by 2026. This remarkable figure

highlights the growing reliance on recycled materials to reduce waste and conserve energy. Sustainability isn't

just a trend; it's a necessity.

Innovations like automated sorting technologies are revolutionizing how

materials are processed. Automated systems increase efficiency, allowing the recovery of up to

97% of recyclable metal. However, the adoption rate remains low. Many

facilities still rely on outdated methods. Continuous training and investment are crucial for long-term success

in sustainable recycling.

While the industry shows promise, challenges persist. Contamination

of recyclable materials remains a significant hurdle. The recycling of metals such as aluminum can drop by over

30% when mixed with other substances. This emphasizes the need for more

public education on proper recycling practices. Poor awareness hinders

progress toward a more sustainable future in metal recycling.

The circular economy transforms metal recycling. It emphasizes resource efficiency and waste reduction. By reusing materials, we can lessen the need for virgin resources. This approach promotes innovative recycling methods. Advanced technologies are now being developed to separate metals more effectively.

Incorporating circular principles, companies are exploring closed-loop systems. These systems minimize waste and maximize material usage. Challenges remain, though. Not all materials are easily recyclable. Some still end up in landfills. Improving this is vital as we strive for sustainability.

Education is key in this transition. Awareness can drive consumer choices towards recycled products. However, the recycling infrastructure still has gaps. Investment in technology and processes is essential. Continuous improvement is needed to achieve true circularity in metal recycling.

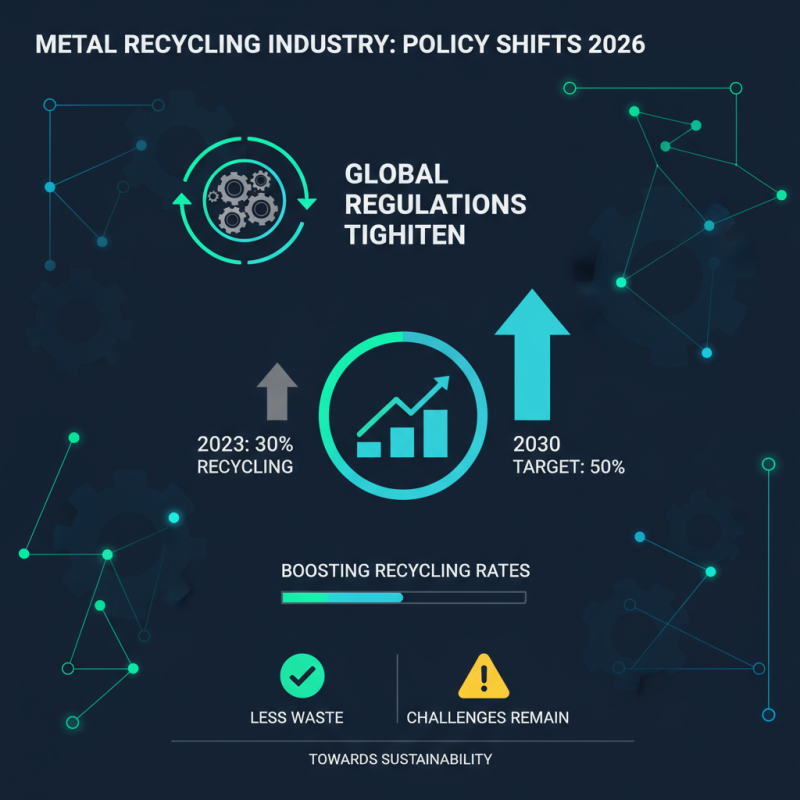

Policy changes are shaping the metal recycling industry significantly in 2026. Governments worldwide are implementing stricter regulations. These aim to improve recycling rates and reduce waste. According to a recent report, global recycling rates for metals stood at only 30% in 2023. The goal is to boost this number to 50% by 2030. While this looks promising, challenges remain.

New tax incentives are encouraging companies to invest in sustainable practices. Manufacturers are now focusing on eco-friendly metals. Meanwhile, there are fears that the costs of compliance may stifle smaller businesses. A study found that 70% of small recycling firms may struggle with these changes. This indicates a need for support and resources to adapt to the evolving landscape.

Additionally, international trade policies are shifting, impacting metal exports. Some countries are banning the export of certain waste metals. This directive is aimed at promoting domestic recycling. Yet, it could lead to an oversupply of materials locally, causing a market imbalance. Industry players must navigate these complexities efficiently to thrive.

Consumer awareness plays a crucial role in metal recycling efforts. Recent studies indicate that informed consumers are more likely to recycle. A 2023 report showed that 75% of individuals prefer using products made from recycled metals. This reflects a growing consciousness about environmental impact. Educational campaigns have increased participation rates in recycling programs.

Moreover, many communities have initiated local workshops. They aim to teach the public about proper recycling practices. However, challenges remain. A surprising 40% of respondents admitted they were unsure about what materials are recyclable. This confusion leads to contamination in recycling streams. Contaminated materials often end up in landfills, negating environmental benefits.

Despite these obstacles, advancements in technology assist consumers. Apps that identify recyclable items have gained popularity. Moreover, partnerships between municipalities and tech firms have improved collection efficiency. Yet, participation is still inconsistent across regions. Innovative solutions are needed to bridge these gaps in consumer involvement. Engaging more individuals in the recycling process can drastically enhance recovery rates and foster sustainable practices.