Leave Your Message

In the ever-evolving landscape of industrial manufacturing, the adoption of innovative technologies is paramount for improving efficiency and sustainability. One such advancement is the Metal Briquette Machine, which has emerged as a crucial tool in metal processing operations. According to a market report by Research and Markets, the metal recycling industry is projected to reach $409.21 billion by 2026, with briquetting technologies playing a vital role in optimizing material handling and reducing waste.

The Metal Briquette Machine streamlines the recycling process by compacting metal shavings and dust into dense briquettes that can be easily stored and transported. This not only enhances storage efficiency but also minimizes the environmental impact of metal waste. Furthermore, studies indicate that using a briquetting machine can significantly reduce operational costs, with facilities reporting savings of up to 30% on raw material procurement. As industries increasingly focus on sustainability and cost-effectiveness, the Metal Briquette Machine stands out as an essential investment for businesses looking to enhance their profitability while contributing to circular economy practices.

Metal briquette machines play a crucial role in the recycling and waste management industry by efficiently compacting metal shavings and scrap into dense briquettes. These machines function by applying high pressure to the metal waste, reducing its volume and making it easier to handle, transport, and sell. According to a report by Grand View Research, the global metal recycling market is expected to reach USD 546.2 billion by 2025, highlighting the increasing importance of efficient metal waste processing solutions. Metal briquettes not only simplify logistics but also optimize storage space, allowing businesses to boost their operational efficiency.

Understanding the functionality of metal briquette machines reveals several economic advantages for businesses in metalworking industries. By converting scrap into valuable briquettes, companies can enhance their revenue stream while promoting environmentally sustainable practices. The European Commission’s report suggests that recycling metal can save up to 95% of the energy required to produce new metal from ore, making briquette machines an eco-friendly choice. Furthermore, the compacted briquettes can be easily used as a feedstock in steelmaking processes, thus creating a circular economy that benefits both the industry and the environment.

Using a metal briquette machine significantly enhances efficiency in metal scrap processing, which is crucial for businesses looking to optimize their operations. According to a report from the Metal Recycling Association, companies that implement briquette machines can achieve up to a 90% reduction in metal scrap volume. This remarkable efficiency not only conserves space but also minimizes handling costs and labor, leading to substantial savings over time. With reduced material wastage, businesses can maximize the value obtained from their scrap metal.

Moreover, briquetting technology contributes to a more sustainable operation by ensuring that the processed metal can be reused or recycled easily. The International Recycling Bureau estimates that the recycling of metals saves 74% of the energy required to create new metal from raw materials. By utilizing a briquette machine, businesses simplify the recycling process, making it more accessible and efficient. This not only supports environmental goals but also aligns with legislative pressures for increased sustainability in industrial practices. Overall, embracing a metal briquette machine stands out as a strategic move for businesses aiming to streamline their scrap processing capabilities while fostering a greener operational footprint.

The adoption of metal briquette machines can significantly bolster cost savings and economic benefits for businesses across various sectors. According to industry reports, companies utilizing this technology can reduce their metal waste by up to 80%, translating into substantial savings on raw material costs. By transforming scrap metal into compact briquettes, manufacturers not only efficiently recycle their waste but also create a valuable product that can be resold or reused in production processes. This reprocessing can lead to a decrease in the purchase of virgin materials, which, in addition to saving costs, supports sustainability initiatives—a growing concern among modern enterprises.

Furthermore, the energy savings associated with metal briquette technology cannot be overlooked. Research indicates that converting metal scraps into briquettes can lead to energy savings of approximately 30-50% during the smelting process. This reduction in energy consumption not only lowers operational costs but also minimizes the carbon footprint of metal production. For businesses looking to optimize both their financial and environmental performance, investing in metal briquette machines presents a compelling case for improved efficiency and cost-effectiveness, making it a strategic choice in the competitive manufacturing landscape.

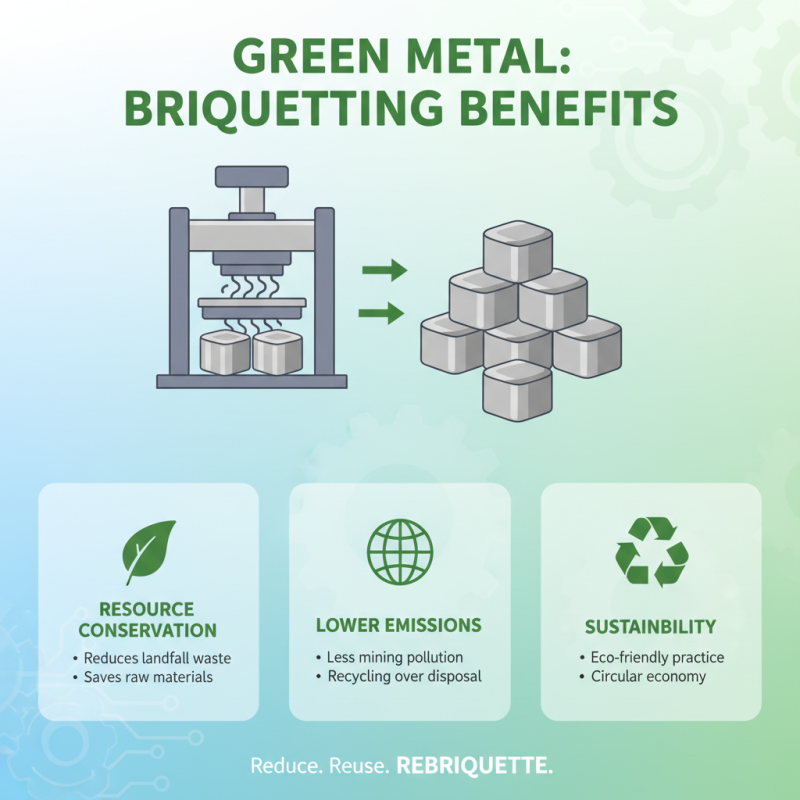

Metal briquetting offers significant environmental advantages, particularly for businesses looking to adopt sustainable practices. By recycling metal waste into dense briquettes, companies can drastically reduce the volume of scrap metal heading to landfills. This not only conserves valuable natural resources but also minimizes the environmental impact associated with mining and refining new metals. Additionally, using a metal briquette machine can lower greenhouse gas emissions by promoting recycling over traditional disposal methods.

Tips for implementing metal briquetting in your business include assessing your current metal waste output and evaluating different briquette machine options that suit your operational needs. It's also beneficial to train your staff on the importance of recycling and how to operate the briquette machine effectively. This fosters a culture of sustainability within your organization, encouraging employees to be more mindful of waste management practices.

Moreover, consider collaborating with other businesses in your industry to share insights on metal briquetting techniques and best practices. By doing so, you not only enhance your environmental responsibility but also foster a community focused on sustainable development. Embracing metal briquetting can lead to cost savings and improved environmental performance, positioning your business as a leader in sustainability.

Metal briquette machines are gaining traction across various industries due to their ability to efficiently process metal wastes into compact briquettes. These briquettes can be easily stored and transported, making them a valuable asset for manufacturers in sectors such as automotive, aerospace, and metal recycling. The automotive industry, in particular, benefits from metal briquette machines, as they help in recycling scrap metal generated during production, reducing waste and lowering operational costs.

In addition to the automotive sector, foundries and metal workshops find metal briquette machines beneficial for enhancing efficiency. By compacting metal chips and shavings, these machines help reduce the volume of waste materials, thus optimizing storage space and facilitating better workflow. Moreover, the compacted briquettes can be melted down and reused in production processes, promoting sustainability and cutting down on material costs.

Tips: To maximize the benefits of metal briquette machines, ensure that they are properly maintained and calibrated for your specific production needs. Regular inspections can prevent downtime and extend the lifespan of the equipment. Additionally, training operators on the best practices for using these machines can lead to improved efficiency and output quality.

| Benefit | Application | Industry | Impact |

|---|---|---|---|

| Space Saving | Metal Recycling | Manufacturing | Reduces storage for scrap metals |

| Increased Value | Briquette Production | Energy | Higher selling prices for briquettes |

| Waste Reduction | Material Processing | Construction | Lowers disposal costs by minimizing waste |

| Enhanced Efficiency | Automated Production | Metalworking | Streamlines the production process |

| Improved Safety | Handling Hazardous Materials | Recycling | Reduces risk of injuries during handling |

| Sustainability | Eco-Friendly Practices | Waste Management | Promotes green initiatives and reduces carbon footprint |