Leave Your Message

When it comes to maximizing the efficiency and effectiveness of heavy equipment in demolition projects, selecting the right demolition attachments is crucial. These attachments, such as hydraulic hammers, shears, and buckets, play a significant role in determining how well a demolition task is executed. The right choice can enhance productivity, reduce operational costs, and ensure safety on the job site. Given the variety of available options, it's essential for contractors and operators to understand the specific needs of their projects to make informed decisions.

Choosing the ideal demolition attachments involves considering factors such as the type of material to be demolished, the scale of the project, and compatibility with the existing machinery. A thoughtful evaluation of these elements not only aids in selecting the most effective attachments but also contributes to the overall success of the demolition process. As project requirements vary widely, understanding the intricacies of different attachments allows for tailored solutions that can address unique challenges presented by each job site. Ultimately, investing time in this decision-making process will lead to better outcomes and greater efficiency in demolition operations.

When it comes to demolition projects, selecting the appropriate attachments for heavy equipment can significantly impact efficiency and safety. Various types of demolition attachments cater to different tasks, and understanding their functionalities is crucial. For instance, hydraulic hammers are commonly used for breaking concrete and rock, delivering powerful force through repeated impacts. According to the Construction Equipment Guide, the demand for hydraulic hammers was projected to grow by 4.5% annually from 2022 to 2027, highlighting their essential role in modern demolition.

Another vital category includes excavator attachments such as shears and grapples. These tools are designed for precise cutting and material handling, allowing operators to tackle complex structures with greater accuracy. A report by the International Data Corporation noted that the market for demolition attachments is expected to reach $3.5 billion by 2025, driven by advanced engineering and the increasing complexity of demolition projects. Understanding the specific requirements of each task will enable contractors to choose the right attachments that enhance productivity and ensure safety on site.

| Attachment Type | Description | Ideal Uses | Weight (lbs) | Compatibility |

|---|---|---|---|---|

| Hydraulic Breaker | Delivers powerful strikes to break concrete and rock. | Concrete breaking, excavation. | 500 - 3000 | Excavators, skid steers. |

| Concrete Crusher | Crushes concrete structures for reuse. | Recycling concrete, demolition. | 800 - 4000 | Excavators. |

| Multiprocessor | Versatile attachment for cutting, crushing, and sorting. | Selective demolition, scrap handling. | 1500 - 6000 | Excavators. |

| Shears | Cuts through steel and metal structures. | Metal demolition, scrap processing. | 1200 - 5000 | Excavators, loaders. |

| Ripper | Breaks up hard ground and rock formations. | Site preparation, land clearing. | 600 - 2500 | Excavators, dozers. |

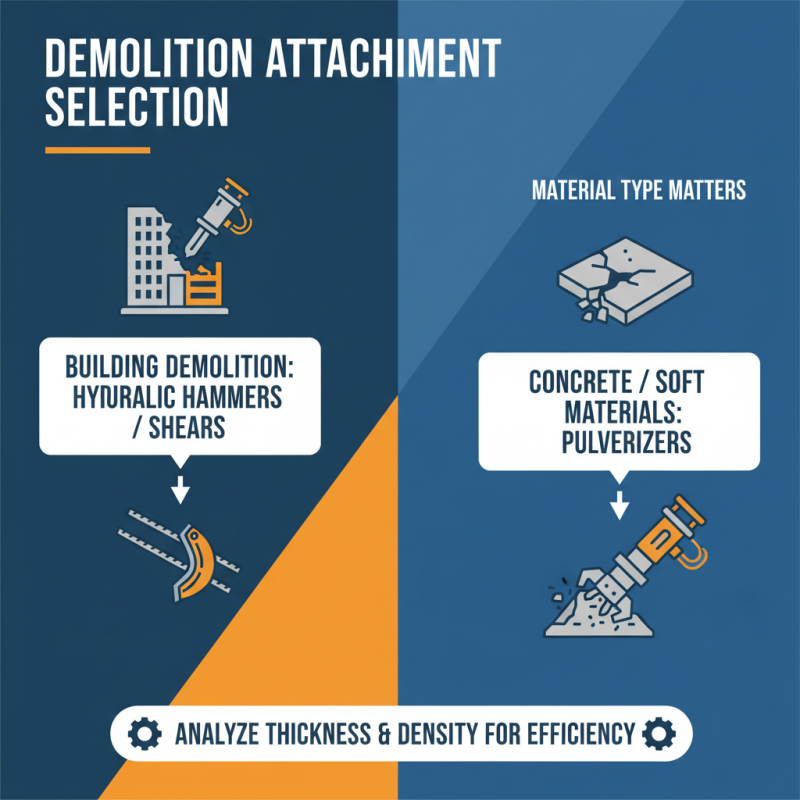

When selecting demolition attachments for heavy equipment, it is essential to consider the specific job type at hand. Different demolition projects require different tools; for instance, a building demolition may call for hydraulic hammers or shears, while a softer material such as concrete could be best handled with pulverizers. Understanding the material you will be working with is critical, as this will influence both the effectiveness and efficiency of your chosen attachment. Analyzing the thickness and density of the materials involved will guide your choice, ensuring that the attachment can handle the demands of the task without excessive wear or risk of failure.

Another key consideration is the size and weight of the heavy equipment itself. Attachments need to be compatible with the machine in terms of hydraulic flow and overall capacity. For example, a larger excavator might require robust attachments that can withstand higher loads, while smaller machines can utilize lighter, more versatile tools. Additionally, job site constraints such as space and height can affect the attachment's performance. It's important to assess the working environment carefully and select attachments that not only match the equipment specifications but also suit the operational space available, ensuring maximum safety and productivity during demolition operations.

When selecting demolition attachments for heavy equipment, one of the most critical factors to consider is their compatibility with equipment specifications and brands. According to a report by the Construction Equipment Industry Association (CEIA), ensuring that attachments align with the specific performance parameters of the machinery can significantly impact operational efficiency. For example, mismatched attachments may lead to increased wear and tear on the equipment, reduced productivity, and even safety hazards on-site. As such, it's essential to review the technical specifications of both the attachments and the machinery, including hydraulic flow rates, weight limitations, and connection types.

Furthermore, understanding the brand compatibility is crucial, as different manufacturers may have varying design standards and specifications. A statistical survey conducted by Machinery Trader revealed that nearly 30% of equipment failures were attributed to the improper use of attachments that were not designed for a specific model. This underlines the need for thorough research and possibly consulting equipment manuals or industry experts to ensure that the chosen demolition attachments will integrate seamlessly with the heavy machinery being used. By prioritizing compatibility, contractors can enhance the longevity of their equipment and maximize their project's efficiency.

When selecting demolition attachments for heavy equipment, one of the foremost considerations is their durability. The harsh environments in which these tools operate require materials that can withstand significant wear and tear. Steel quality, heat treatment processes, and overall construction contribute to an attachment's lifespan. Understanding the specific demands of your projects—such as the types of materials being demolished and the frequency of use—can help in making an informed decision. Attachments that exhibit high robustness not only reduce the frequency of replacements but also ensure consistent performance, minimizing downtime during critical operations.

Another critical factor to consider is the maintenance requirements of the demolition attachments. Tools that are designed for easier maintenance can save both time and money in the long run. It's essential to evaluate aspects like the accessibility of replaceable parts, the complexity of servicing, and the recommended maintenance schedules provided by manufacturers. Regular inspections and minor repairs can significantly extend the life of any attachment, ensuring they remain efficient and effective throughout their operation. By prioritizing both durability and straightforward maintenance, operators can optimize productivity and enhance the reliability of their heavy equipment in demolition projects.

When considering the purchase of demolition attachments for heavy equipment, a cost-benefit analysis becomes crucial. High-quality attachments often come with a higher upfront cost, but they typically provide long-term savings and improved performance. Industry reports indicate that investing in durable attachments can enhance productivity by as much as 30%, reducing downtime and maintenance costs associated with lower-quality options. For instance, projects that utilize premium attachments have documented a significant decrease in wear and tear, ultimately leading to a longer equipment lifespan and lower total ownership costs.

Conversely, budget attachments may seem economically advantageous at first glance, but they often incur additional expenses that can quickly outweigh initial savings. Research shows that lower-cost attachments can lead to more frequent repairs and replacements, which not only disrupt project timelines but also increase operational costs over time. In fact, a recent industry analysis revealed that companies opting for economical attachments found themselves spending nearly 50% more on maintenance in a five-year period compared to those that invested in higher-quality products. This highlights the importance of evaluating the long-term financial implications when selecting demolition attachments, as a well-informed decision can significantly impact a project’s overall profitability and efficiency.