Leave Your Message

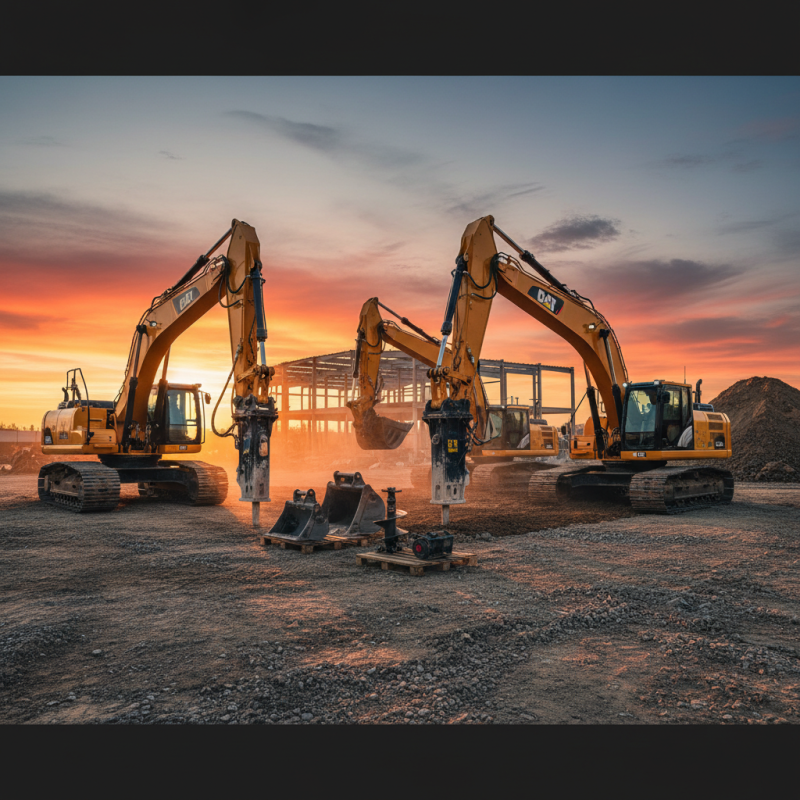

In the world of construction and excavation, the efficiency of a project can hinge significantly on the tools and equipment used. One critical aspect of this is the selection of the right attachments for excavators. According to John Smith, an expert in heavy machinery and attachments, “Choosing the right attachments can mean the difference between a job well done and costly delays.” This notion emphasizes the importance of not only understanding the capabilities of the excavator itself but also recognizing how various attachments can enhance productivity and adaptability on the job site.

Attachments for excavators come in a variety of forms, each designed to tackle specific tasks ranging from digging and grading to demolition and lifting. The correct selection of these attachments can greatly influence operational efficiency, project timelines, and overall cost-effectiveness. As construction projects become increasingly complex, the ability to choose the right attachments becomes even more essential. By equipping excavators with the proper tools, operators can maximize their effectiveness while navigating the diverse challenges presented by each job.

In conclusion, understanding the pivotal role of attachments for excavators is crucial for construction professionals seeking to improve their operational workflows and outcomes. With the right attachments, teams can achieve greater efficiency and ensure that their projects are completed on time and within budget.

The importance of attachments in excavator efficiency cannot be overstated. Attachments are key tools that can significantly enhance the versatility and functionality of an excavator. By selecting the right attachments, operators can adapt their machines to perform a wide range of tasks, from digging and grading to demolition and material handling. This adaptability not only maximizes operational capabilities but also increases productivity, allowing projects to be completed more quickly and effectively.

Moreover, the correct attachments can lead to improved fuel efficiency and reduced wear and tear on the equipment. When operators choose attachments that are specifically designed for their tasks, they can optimize flow and force, which translates into smoother operation and less strain on the excavator. This not only prolongs the life of the equipment but also reduces maintenance costs, ultimately contributing to a more cost-effective operation. In this context, making an informed choice about attachments is essential for achieving peak performance in any excavation project.

When it comes to excavators, selecting the right attachments is essential for maximizing operational efficiency and productivity on job sites. Various attachments serve different functions, allowing excavators to adapt to a range of tasks. For instance, bucket attachments are widely used for digging and moving materials, with sizes varying from compact to large for different applications. Utilizing the correct bucket size can enhance material handling capacity by up to 20%, significantly influencing project timelines and cost efficiency.

In addition to buckets, other attachments such as hydraulic hammers, grapples, and augers offer specialized functionalities. Hydraulic hammers, used for breaking concrete or rock, can increase excavation speed by 30%, drastically reducing labor hours required for demolition. Grapples, on the other hand, are ideal for handling debris and waste, promoting better organization on construction sites. A study by the Construction Industry Institute indicates that integrating the right attachment can lead to a 25% improvement in project workflow, proving that informed attachment choices are critical not only for performance but also for overall operational efficacy in heavy machinery sector.

Choosing the right attachments for excavators is a key factor in maximizing operational efficiency and productivity on construction sites. One of the primary considerations is the type of material the excavator will be working with. According to a study by the Construction Industry Institute, selecting compatible attachments can enhance productivity by up to 30%, particularly when they are tailored for specific tasks such as digging, grading, or demolition. The mismatches between attachment and task can lead to increased wear and tear on equipment, resulting in more frequent maintenance and associated costs.

Another significant factor is the weight and size of the attachments. Overloading an excavator with unsuitable attachments can compromise stability and reduce overall effectiveness. Research shows that the optimal weight-to-capacity ratio should not exceed 80%, ensuring that operators can maintain control while performing intricate tasks. Additionally, considering the hydraulic flow rate and pressure of the excavator is essential; attachments that require more hydraulic power than the excavator can supply will not operate efficiently, leading to decreased performance and potential damage. Thus, taking these factors into account when selecting excavator attachments is vital for ensuring not only efficiency but also the longevity of the machinery.

Selecting the right attachments for excavators is essential for maintaining project efficiency and adhering to timelines. The choice of attachments directly influences not only the speed at which tasks are completed but also the quality of the work being done. For instance, using a bucket designed for specific materials can significantly reduce the amount of rework required, thereby keeping the project on schedule. When contractors opt for the correct attachments, they mitigate the risk of delays caused by inefficient tools or the need for additional equipment.

Tips for choosing attachments include assessing the project's specific requirements and the nature of the materials being handled. Compatibility between the excavator and the attachment is crucial to ensure optimal performance. Additionally, consider the versatility of attachments; a multipurpose tool can save time and resources by accommodating various tasks without the need for frequent changes. Proper training for operators on different attachments can also enhance productivity and reduce potential downtime.

In conclusion, a well-thought-out attachment selection process is integral to maintaining efficiency within any excavation project. By investing time in understanding the impact of each attachment on project outcomes, contractors can make informed decisions that enhance productivity and ensure timely completion of projects.

| Attachment Type | Project Type | Efficiency Gain (%) | Average Time Saved (Days) | Cost Impact ($) |

|---|---|---|---|---|

| Digging Bucket | Excavation | 30 | 10 | 5000 |

| Hydraulic Hammer | Demolition | 40 | 5 | 7000 |

| Grading Blade | Site Preparation | 25 | 8 | 3000 |

| Auger | Post Hole Digging | 35 | 6 | 2500 |

| Thumb | Material Handling | 20 | 7 | 1500 |

Maintaining excavator attachments is vital for ensuring optimal performance and extending their operational lifespan. Regular inspections and maintenance will help avoid costly repairs and minimize downtime. Studies indicate that poorly maintained attachments can lead to a 30% reduction in efficiency, significantly impacting project timelines and budgets. Additionally, equipment failure resulting from neglect can lead to safety hazards on job sites. Therefore, implementing a structured maintenance routine is essential for achieving maximum operational productivity.

One effective tip for maintaining excavator attachments is to establish a clean routine. Regularly cleaning attachments post-use can prevent debris build-up, which might cause wear and tear or impede functionality. Furthermore, lubricating moving parts is crucial. A report from the Association of Equipment Manufacturers highlights that proper lubrication can reduce friction, enhancing performance and prolonging component durability by up to 25%.

Another essential aspect of attachment care is monitoring wear indicators. Many attachments come equipped with wear plates that signal when replacement is necessary. Utilizing these indicators not only helps maintain efficiency but also minimizes the risk of unexpected failures. By proactively addressing wear and tear, operators can ensure their excavators remain reliable and efficient throughout their operational lifespan.