Leave Your Message

When it comes to optimizing resources and enhancing operational efficiency, selecting the right scrapping machine is crucial for any business. Industry expert Dr. James Thompson, a leading authority in manufacturing technology, emphasizes, "The effectiveness of your scrapping machine can significantly influence your overall productivity and waste management." As businesses increasingly aim to streamline processes and reduce costs, the decision-making process for acquiring a scrapping machine becomes paramount.

Choosing a scrapping machine tailored to your specific business needs involves analyzing various factors such as capacity, efficiency, and versatility. Whether you are in the recycling sector, manufacturing, or any industry that generates scrap materials, understanding the features and capabilities of different models can help you make an informed choice. By doing so, businesses can ensure that their scrapping machine not only meets current requirements but is also adaptable for future demands, paving the way for sustainable growth and operational excellence.

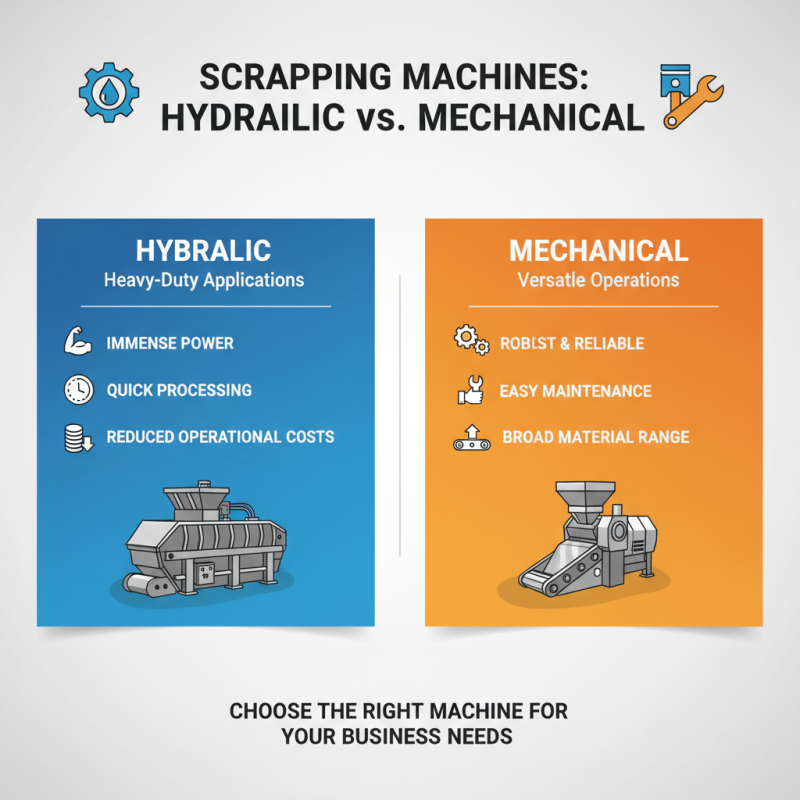

When selecting a scrapping machine for your business, understanding the various types available is crucial to meeting your specific operational needs. The two primary categories of scrapping machines are hydraulic and mechanical machines. Hydraulic scrapping machines utilize high-pressure fluid to operate, making them ideal for heavy-duty applications. They are often favored for their immense power and efficiency in handling tough materials, facilitating quick processing times and reduced operational costs.

On the other hand, mechanical scrapping machines employ gears and levers to perform their functions, which makes them suitable for lighter materials and less intense operations. These machines are typically easier to maintain and provide a cost-effective solution for businesses with lower production demands. Additionally, there are specialty scrapping machines designed for specific tasks, such as wire stripping or metal cutting, which can enhance efficiency for particular materials or processes. Choosing the right type requires careful analysis of the materials you will be handling and the volume of work anticipated in your operations.

When selecting the best scrapping machine for your business, it's vital to assess your unique business needs, particularly regarding capacity and the types of materials you'll be processing. Start by evaluating your production volume requirements—how much material you need to scrap daily, weekly, or monthly. A high-capacity machine may be necessary for businesses handling large volumes, while smaller operations may benefit from more compact models. Understanding your throughput helps ensure efficiency, minimizes delays, and meets customer demands effectively.

Material considerations are equally important in the decision-making process. Different scrapping machines are designed to handle various types of materials, such as metals, plastics, or textiles. Assess the characteristics of the materials you will be working with, including their thickness, hardness, and density. Some machines are better suited for specific materials, while others offer versatility. Evaluating these factors will not only enhance the performance of your scrapping processes but also prolong the lifespan of your equipment, leading to greater cost-effectiveness in the long run.

When choosing a scrapping machine for your business, it’s essential to focus on key features that can enhance efficiency and performance. First, consider the machine's cutting power and speed. A robust motor paired with high-quality blades ensures that materials are processed quickly and effectively, minimizing downtime. Look for machines that offer adjustable speed settings, allowing you to tailor operations based on the specific materials you're working with. This flexibility can greatly improve productivity and adaptability in various projects.

Another crucial aspect is the machine's safety features. Scrapping tasks often involve heavy and sharp objects, so it's vital to choose a model equipped with appropriate safety guards and emergency shut-off switches. Additionally, ergonomic design elements can significantly reduce operator fatigue during extended use. Features such as noise reduction technology and vibration control will also contribute to a safer and more comfortable working environment.

Lastly, consider the durability and ease of maintenance of the scrapping machine. Machines made from high-quality, corrosion-resistant materials are likely to withstand the rigors of daily use. Furthermore, accessible parts for cleaning and repair can save time and reduce long-term operational costs. A machine that is easy to service and maintain will ensure consistent performance and reliability over the lifespan of your equipment.

When selecting a scrapping machine, understanding the cost implications is crucial. The initial investment typically varies based on the machine’s capabilities, with prices ranging from a few thousand dollars for basic models to tens of thousands for advanced options equipped with automation features. According to a recent industry report by IBISWorld, the scrapping machinery market has experienced a 5% annual growth, indicating a rising demand for efficient solutions that can justify these upfront costs through enhanced productivity.

Long-term savings and efficiency are where the true value of a scrapping machine lies. A comprehensive analysis by Market Research Future illustrates that businesses can save up to 30% on operational costs after implementing an efficient scrapping solution. This savings arises from reduced labor hours, minimized material wastage, and increased recycling rates. Additionally, automation features enable 24/7 operations, significantly boosting output. Therefore, while the initial investment may seem daunting, the potential for long-term reductions in labor costs and operational efficiency highlights the importance of a thorough cost-benefit analysis before making a purchase decision.

| Machine Type | Initial Investment ($) | Annual Operating Cost ($) | Expected Lifespan (Years) | Estimated Annual Savings ($) | Efficiency Rating (%) |

|---|---|---|---|---|---|

| Hydraulic Scrapper | 15,000 | 2,500 | 10 | 5,000 | 85 |

| Electric Scrapper | 12,000 | 1,800 | 8 | 4,000 | 90 |

| Pneumatic Scrapper | 18,000 | 3,200 | 12 | 6,500 | 80 |

| Manual Scrapper | 5,000 | 1,000 | 5 | 1,200 | 70 |

| Robotic Scrapper | 25,000 | 4,000 | 15 | 8,000 | 95 |

When selecting a scrapping machine for your business in 2023, it's essential to explore the top brands and models currently dominating the market. Not only do these machines enhance efficiency in your operations, but they also vary in features and specifications that cater to different needs. Some machines are designed for heavy-duty tasks, while others focus on compact size and versatility, making them suitable for smaller enterprises or specialized operations.

Tips: Before choosing a scrapping machine, assess the scale of your operations. If you anticipate high volumes of scrap material, consider models with faster processing speeds and larger capacities. Additionally, look for machines with advanced technology that increases durability and reduces maintenance costs. Features like easy servicing access and user-friendly interfaces can also significantly improve your workflow.

Also, consider the energy efficiency of the machines. An efficient scrapping machine not only saves on electricity bills but can also be an environmentally responsible choice. Prioritize brands that focus on innovation and sustainability, as they often provide products that align with contemporary business values. By evaluating these factors, you can identify a scrapping machine that not only fulfills your operational requirements but also complements your overall business strategy.