Leave Your Message

The hydraulic extrusion press is a vital tool in the metal forming industry. According to a recent industry report, the global market for hydraulic presses is projected to grow significantly due to increasing demand for lightweight materials. This growth is expected to drive innovations in technologies, including hydraulic extrusion processes.

Efficient metal forming is critical for various applications, such as automotive and aerospace industries. However, many manufacturers struggle with optimization. Challenges like cycle time, energy consumption, and maintenance costs can hinder productivity. The hydraulic extrusion press, with its ability to produce complex shapes, offers a solution. Yet, much remains to be improved in operational techniques.

Adopting best practices can enhance the overall efficiency of a hydraulic extrusion press. Understanding die design, material properties, and process parameters is essential. Setting clear objectives for production can also help identify opportunities for improvement. Continuous learning from each process will ultimately lead to more effective metal forming operations.

Hydraulic extrusion presses play a crucial role in metal forming. These machines apply high pressure to shape metal into desired forms. According to industry studies, the global hydraulic press market is anticipated to reach $10 billion by 2025. This growth reflects increased demand in sectors like automotive and aerospace.

Understanding the basics of this technology is essential for efficient operation. Typically, a hydraulic press operates using Pascal's law, where pressure applied to a confined fluid is transmitted undiminished. This principle allows for high force generation with relatively small input power. Operators must remain vigilant about maintenance. Regular checks on hydraulic fluid levels and seals are vital to prevent leaks.

Tip: FAQs for Operators

Always keep a detailed log of machine usage and maintenance. Use this log to identify patterns that might indicate issues.

Maintain an awareness of safety standards. Regular training sessions for operators can mitigate risks. In some cases, operators may overlook minor malfunctions. These can lead to larger, more expensive issues down the line. Investing time in early problem detection is worth the efforts.

In conclusion, understanding hydraulic extrusion press technology enhances productivity. Familiarizing with its operational nuances will improve metal forming outcomes significantly.

Hydraulic extrusion presses are vital in metal forming. Understanding their key components helps in optimizing the process. At the core is the hydraulic cylinder. This cylinder generates the powerful force needed to extrude metal. It’s crucial for transforming raw materials into desired shapes.

Next is the extrusion die. This die shapes the metal as it flows through. The die must be precisely designed to ensure accuracy. A poorly crafted die can lead to defects, wasting materials and time. Users must regularly inspect and maintain it to avoid these issues.

Another important component is the control system. It regulates the pressure and speed during the extrusion process. An effective control system allows for adjustments in real-time. However, sometimes, operators struggle with consistent settings. This inconsistency can affect the final product's quality. Learning from these challenges can lead to improvements in both technique and equipment handling.

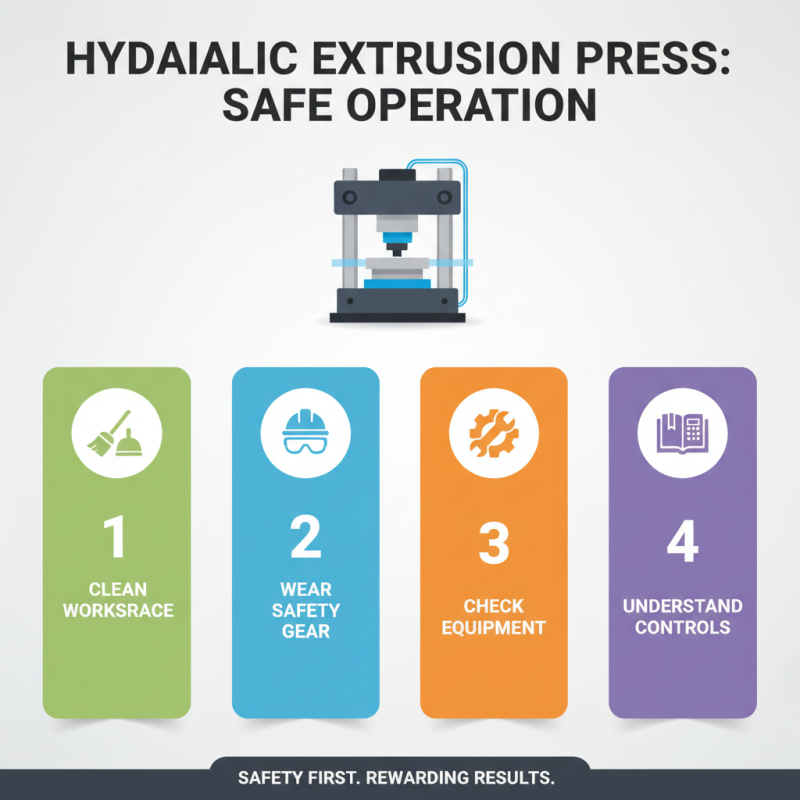

Operating a hydraulic extrusion press is a complex yet rewarding task. Begin by ensuring your workspace is clean and organized. Safety is crucial; wear appropriate gear. Check all equipment for wear and damages. You need to understand the machine's manual thoroughly. Familiarize yourself with the controls before starting.

Next, prepare your metal material. Cut it to the desired size. Heating the metal can improve flow during extrusion. Many operators ignore this step, leading to poor results. After preparing, load the material into the press. Adjust the parameters based on what you're forming. It's essential to monitor pressure closely during the process. If you notice unusual sounds, stop immediately.

Post-extrusion, inspect the final product carefully. Look for surface imperfections or inconsistencies. Document any issues to improve future processes. Continuous learning is vital when operating a hydraulic press. Reflect on what went well and what didn’t. Every extrusion is a chance to refine your technique.

Maintaining efficiency in metal forming with a hydraulic extrusion press requires attention to detail. Regular maintenance can prevent costly downtimes. According to industry data, improper maintenance can lead to a 25% drop in production efficiency. Ensuring that fluid levels are optimal is essential. Low hydraulic fluid can cause system overheating, which may damage equipment. Surveillance on the temperature levels helps in this regard.

Monitoring wear and tear on dies is another critical practice. Experts recommend inspecting dies after every 100 hours of operation. This practice can significantly extend the life of the press. Reports indicate that worn dies can decrease product quality by 15%, resulting in more scrap and rework. In a competitive market, minimizing scrap is crucial for profitability.

Employee training is often overlooked. Properly trained operators can identify inefficiencies quickly. A survey shows that companies investing in operator training witness a 30% improvement in output quality. Yet, many still skip this vital step. Frequent training sessions should be part of a company’s routine. The investment pays off in both quality and productivity. Regular assessments help identify areas for improvement, even if they make teams uncomfortable.

Hydraulic extrusion is revolutionizing metal forming in various industries. This process utilizes high-pressure fluid to shape metals efficiently. Common applications include creating complex shapes and profiles, which can be challenging with traditional methods.

Industries like automotive and construction benefit greatly from this technique. Lightweight components, often crucial in vehicle design, are easily produced using hydraulic presses.

The efficiency of hydraulic extrusion comes from its ability to minimize waste. Metal is pushed through a die, allowing for precise control over dimensions. This results in uniformity and reduced material loss. However, challenges do exist. For example, achieving perfect surface finishes can require additional steps. Operators must be skilled to adjust pressure and speed properly.

Safety is always a concern in hydraulic operations. Improper setup can lead to accidents or machine failure. Regular maintenance is essential for smooth operation. If the equipment is neglected, even the best designs can result in inefficiencies. Striking a balance between speed and quality is critical. Operators often reflect on their practices to improve outcomes.