Leave Your Message

Material Handlers play a crucial role in various industries. They are responsible for the movement of materials and products. Their tasks include loading, unloading, and transporting goods within warehouses or production facilities.

These dedicated workers help ensure that inventory is organized. Often, they operate forklifts, pallet jacks, or hand trucks. However, not every Material Handler is trained adequately. This can lead to safety issues or inventory mismanagement. Attention to detail is essential in this role, yet some may overlook it.

Many Material Handlers work long hours. This can lead to fatigue, affecting their performance. Reflecting on how to improve processes is vital. Enhancing efficiency while prioritizing safety creates a better work environment for all. The contribution of Material Handlers is often underestimated, yet their impact is significant.

A material handler plays a crucial role in various industries.

They manage, transport, and organize materials within a facility. This role is vital for maintaining efficiency

in warehouses and manufacturing plants. According to the Bureau of Labor Statistics, material handler jobs are

projected to grow by 13% from 2020 to 2030, faster than the average

for all occupations. This growth reflects the expanding demand for logistics and supply chain management.

The daily tasks of a material handler often include loading and unloading materials, operating forklifts,

and maintaining inventory. These professionals must follow safety protocols closely. A report indicates that

improper handling of materials contributes to significant workplace injuries. Surprisingly, about 40% of material handlers report experiencing musculoskeletal disorders due

to repetitive strain. This underlines the importance of proper training

and ergonomic practices.

Despite the clear need for material handlers, some companies overlook training programs. A study revealed

that 25% of material handlers felt ill-equipped for their tasks.

Investing in education and safety measures can be transformative for productivity. However, without

addressing these concerns, the industry risks high turnover rates and increased accidents.

Attention to worker well-being is essential, yet often neglected.

Material handlers play a crucial role in various industries by managing the movement of materials. Their responsibilities are diverse and vital for efficiency. They typically use forklifts, pallet jacks, and conveyor systems to transport goods. According to the Bureau of Labor Statistics, the demand for material handlers is projected to grow by 5% over the next decade, highlighting their importance in supply chain operations.

Key responsibilities include loading and unloading shipments, organizing inventory, and ensuring safe handling practices. Material handlers often conduct inspections of equipment and materials. This attention to detail not only prevents accidents but also helps maintain productivity. Despite the heavy physical demands, many find the work rewarding.

Tip: Always prioritize safety training. It is essential to know how to operate equipment correctly. A single oversight can lead to injuries. Reflect on past mistakes to improve future performance. Communication with teammates is also crucial for efficiency.

Additionally, maintaining an organized workspace can significantly optimize workflow. Efficiency can drop when materials are misplaced. Investing time in organization saves time overall. Materials should be labeled clearly, and storage areas ought to be well-defined.

A material handler plays a crucial role in various industries. This position requires specific skills and qualifications. Successful material handlers must be physically fit. They often lift heavy objects and operate equipment. Safety training is essential. According to industry data, over 25% of injuries in warehouses are linked to improper lifting techniques.

Attention to detail is another key skill. Material handlers must track inventory accurately. Errors can lead to delays and increased costs. Training programs often emphasize the importance of organizational skills. Some reports suggest that up to 30% of material handlers struggle to maintain efficiency due to lack of training.

Communication is also vital. Material handlers must interact with team members and supervisors effectively. Good communication helps prevent mistakes. A survey indicated that about 40% of material handlers feel they need more training in this area. Continuous improvement and feedback can help them grow in their roles.

In material handling, safety is paramount. Workers often move heavy items, which can cause injuries without proper precautions. Implementing safety protocols protects employees and enhances productivity. Each worker must wear the necessary personal protective equipment (PPE). This usually includes safety gloves, helmets, and steel-toed boots.

Tips for safe handling: Always use two hands when lifting. Maintain a clear path to avoid tripping hazards. Regularly inspect your lifting equipment for wear and tear. Training employees in safe operational procedures also contributes significantly to workplace safety. Understanding how to operate machinery can prevent many accidents.

Using the right equipment is crucial. Hand trucks and forklifts are common tools. Workers should know how to use them properly. However, relying solely on equipment can lead to complacency. It’s vital to remember that human judgment plays a crucial role in safety. Regular training sessions keep everyone informed about best practices. Encourage team discussions about safety concerns and improvements.

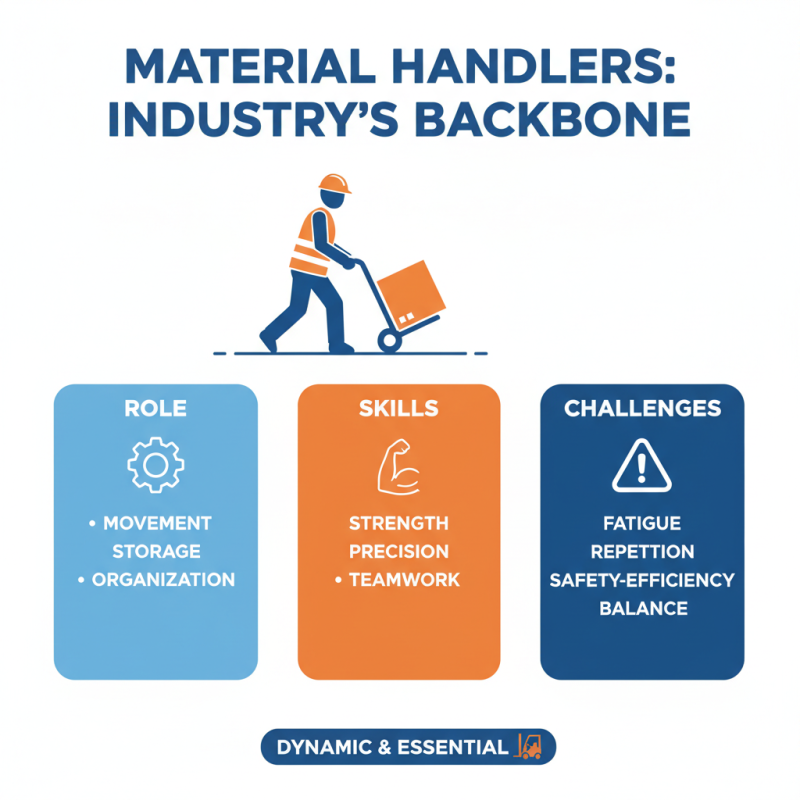

Material handlers play a crucial role in various industries. They manage the movement, storage, and organization of materials. This role is dynamic and requires physical strength, attention to detail, and teamwork. However, it can also involve repetitive tasks that may lead to fatigue. Workers often face challenges in maintaining efficiency while ensuring safety.

Career opportunities in material handling are diverse. Many handlers start in entry-level positions, gaining valuable experience. With dedication, they can advance to supervisory roles or logistics coordination. The potential for growth is significant, but competition can be tough. Employees should focus on developing skills like inventory management and communication. These can pave the way for better roles.

Continuous learning is essential in this field. New technologies and methods emerge regularly. Material handlers can enhance their careers by seeking training and certifications. However, it’s essential to reflect on personal goals and whether this path aligns with them. Career satisfaction comes from both personal and professional growth.