Leave Your Message

Scrap Recycling Equipment plays a vital role in modern waste management. According to industry expert John Smith, "Efficient recycling starts with the right equipment." This highlights the importance of advanced machines in recycling processes. These machines handle various materials such as metals, plastics, and paper. They ensure that valuable resources are recovered from waste.

Many organizations recognize the need for effective Scrap Recycling Equipment. They seek to optimize operations and reduce environmental impact. However, some companies struggle with outdated equipment. This may lead to lower productivity and higher operational costs. Thus, staying updated with technology is essential in this sector.

Recycling is not just a trend; it is essential for sustainability. Scrap Recycling Equipment makes this possible by transforming waste into reusable materials. Yet, there are challenges. Understanding which machinery best suits specific needs requires research and experience. Investing in the right tools can be daunting but necessary for success.

Scrap recycling equipment plays a crucial role in waste management. This machinery helps turn discarded materials into reusable resources. Common types include shredders, balers, and granulators. Each piece is designed to process specific materials, from metals to plastics.

In 2022, the global recycling equipment market was valued near $4 billion. Demand is increasing annually as industries strive for sustainability. Reports suggest that effective scrap recycling can reduce waste by up to 70%. However, many facilities struggle with outdated equipment. This directly affects efficiency and output quality.

Challenges also arise from the varying types of scrap. Mixed materials can complicate the recycling process. Equipment that cannot handle diverse inputs falls short. Often, facilities invest in new technology but overlook maintenance. This leads to costly downtimes. Balancing innovation with proper upkeep remains a significant issue in the industry.

Scrap recycling equipment plays a vital role in waste management. Various types exist, each designed for specific materials and processes. Common equipment includes shredders, balers, and metal crushers. Shredders break down large items into manageable pieces. Balers compact materials into bales, making transportation easier. Crushers are essential for reducing metal scrap into smaller, more manageable sizes.

According to a 2021 report by the Global Recycling Foundation, the recycling industry's value is projected to reach $600 billion by 2025. This growth highlights the importance of efficient recycling equipment. Proper machinery can improve processing speed and reduce waste. A well-functioning system can recycle up to 95% of scrap material effectively.

Tip: Regular maintenance of equipment boosts operational efficiency. Minor issues can lead to significant downtime. One overlooked aspect is the training of operators. Well-trained staff can spot inefficiencies early.

Another crucial piece of scrap recycling equipment is the magnetic separator. This device extracts ferrous metals from mixed waste streams. Fashioning a streamlined recycling process reduces contamination. However, it's important to assess the effectiveness of the entire recycling system regularly. Not all equipment functions optimally in every situation. Continuous improvement is necessary.

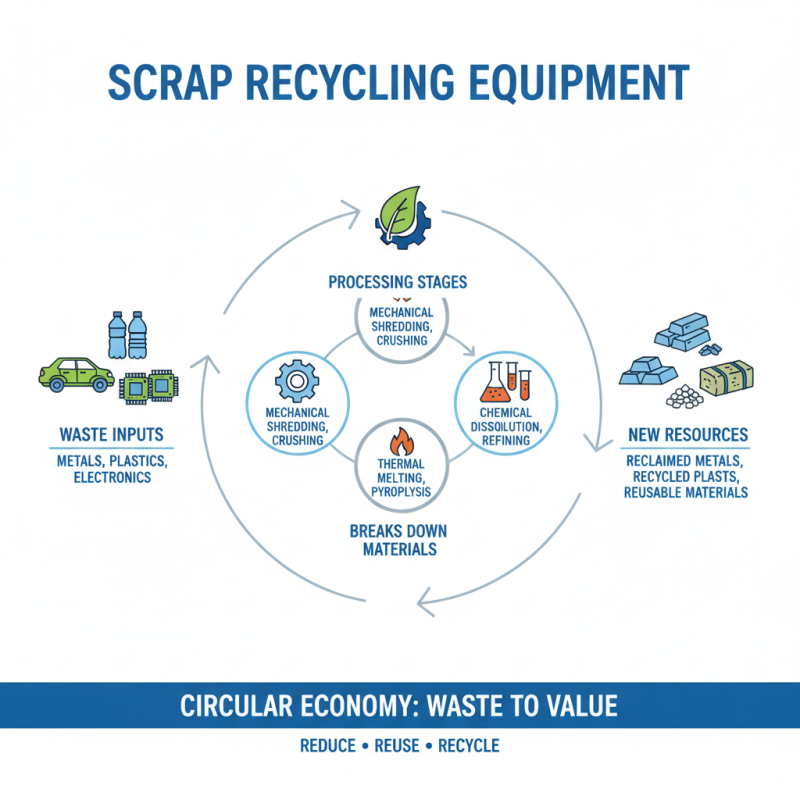

Scrap recycling equipment plays a vital role in the circular economy. It processes various materials, converting waste into valuable resources. The basic working principles hinge on mechanical, thermal, and chemical processes. These methods break down metals, plastics, and other materials efficiently.

Mechanical processing mainly includes shredding and sorting. Shredders reduce large scrap into smaller, manageable pieces. This increases surface area, making further processing easier. After shredding, magnets can separate ferrous metals from other materials. According to the Bureau of International Recycling, about 92% of the iron and steel used worldwide comes from recycled sources. This highlights the importance of effective metal recovery.

Thermal and chemical methods are also significant. Thermal processes involve melting metals, allowing for purification and reformation. Chemical processing can extract specific materials, but it faces challenges. Efficiency often suffers due to contamination. A report from the International Solid Waste Association indicates that up to 30% of recycled materials may not meet quality standards. This poses a real issue for the recycling industry, emphasizing the need for better sorting technology and process optimization.

Scrap recycling equipment plays a crucial role in waste management. It allows us to process and repurpose discarded materials. The technology can separate metals, plastics, and other materials efficiently. This not only conserves natural resources but also reduces landfill waste. When operating this equipment, noise and vibration can be significant. Proper monitoring is essential to ensure both worker safety and equipment longevity.

Using scrap recycling equipment offers several advantages. It promotes environmental sustainability by reducing the need for new raw materials. Fewer resources are extracted, leading to less environmental disruption. Additionally, recycling processes can be energy-efficient, although initial setup costs can be high. The industry also creates jobs and supports local economies. While the benefits are clear, some challenges remain. Training for staff is necessary, and maintenance can be overlooked. Both aspects require ongoing attention to maximize efficiency.

| Equipment Type | Function | Key Advantages | Typical Materials Processed |

|---|---|---|---|

| Metal Shredders | Reduce large metal scrap into manageable pieces. | Increases processing speed and efficiency. | Steel, Aluminum, Copper |

| Baler Machines | Compress materials into bales for easier transport. | Reduces storage space and shipping costs. | Cardboard, Plastics, Metals |

| Wire Strippers | Remove insulation from wires for metal recovery. | Maximizes copper recovery rates. | Electrical Wiring, Cables |

| Granulators | Grind materials into smaller granules. | Enhances recycling process for plastics and rubber. | Plastic Waste, Rubber |

| Magnetic Separators | Separate ferrous materials from non-ferrous materials. | Improves purity of recycled materials. | Metal Shavings, Scrap Yard Waste |

The future of scrap recycling technology is bright yet complex. Innovations are emerging to enhance efficiency and reduce waste. Advanced machinery is now capable of sorting and processing materials with precision. For example, AI can recognize different metals, optimizing the recycling process. This technology can drastically minimize human error.

Moreover, the development of mobile recycling units is noteworthy. These units can be deployed in various locations, making recycling more accessible. It is important to reflect on the limitations of current technology, as not all materials can be processed easily. Some contaminants still pose challenges. Nonetheless, innovations continue to evolve, aiming to tackle these issues.

The impact of these advancements can be profound. They not only improve recycling rates but also foster sustainable practices. However, there remains a gap in public awareness and participation. Engaging communities in recycling efforts is crucial. As technology grows, we must also grow in understanding and commitment. Only then can we fully realize the potential of scrap recycling.