How Do Mobile Shears Work in Recycling Operations

Mobile shears are among the most versatile tools in modern recycling operations. These powerful hydraulic attachments are specifically engineered to cut through metal with precision and force. Designed to handle the toughest materials, mobile shears efficiently process everything from Scrap Metaland steel beams to pipes and complex demolition debris.

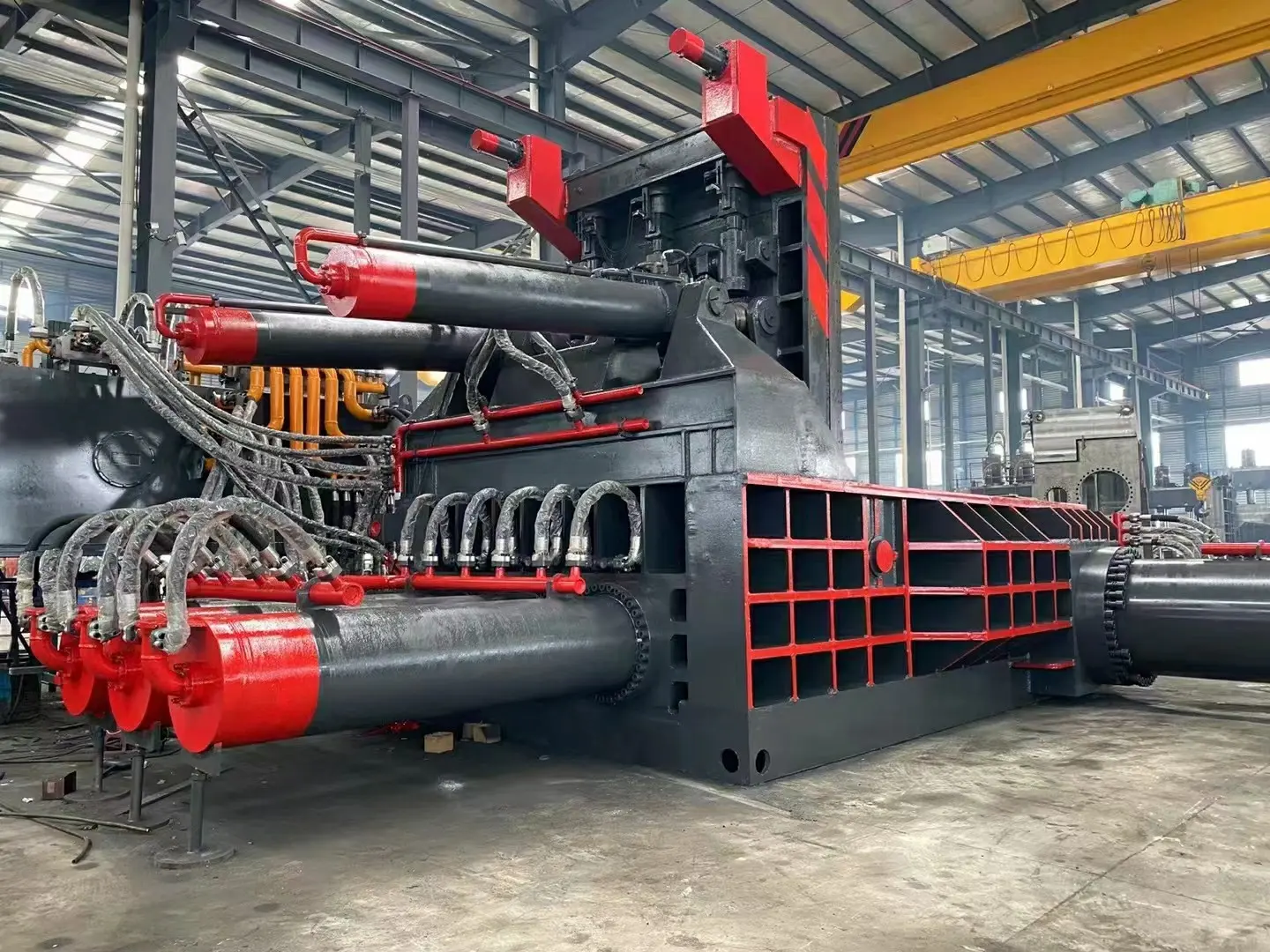

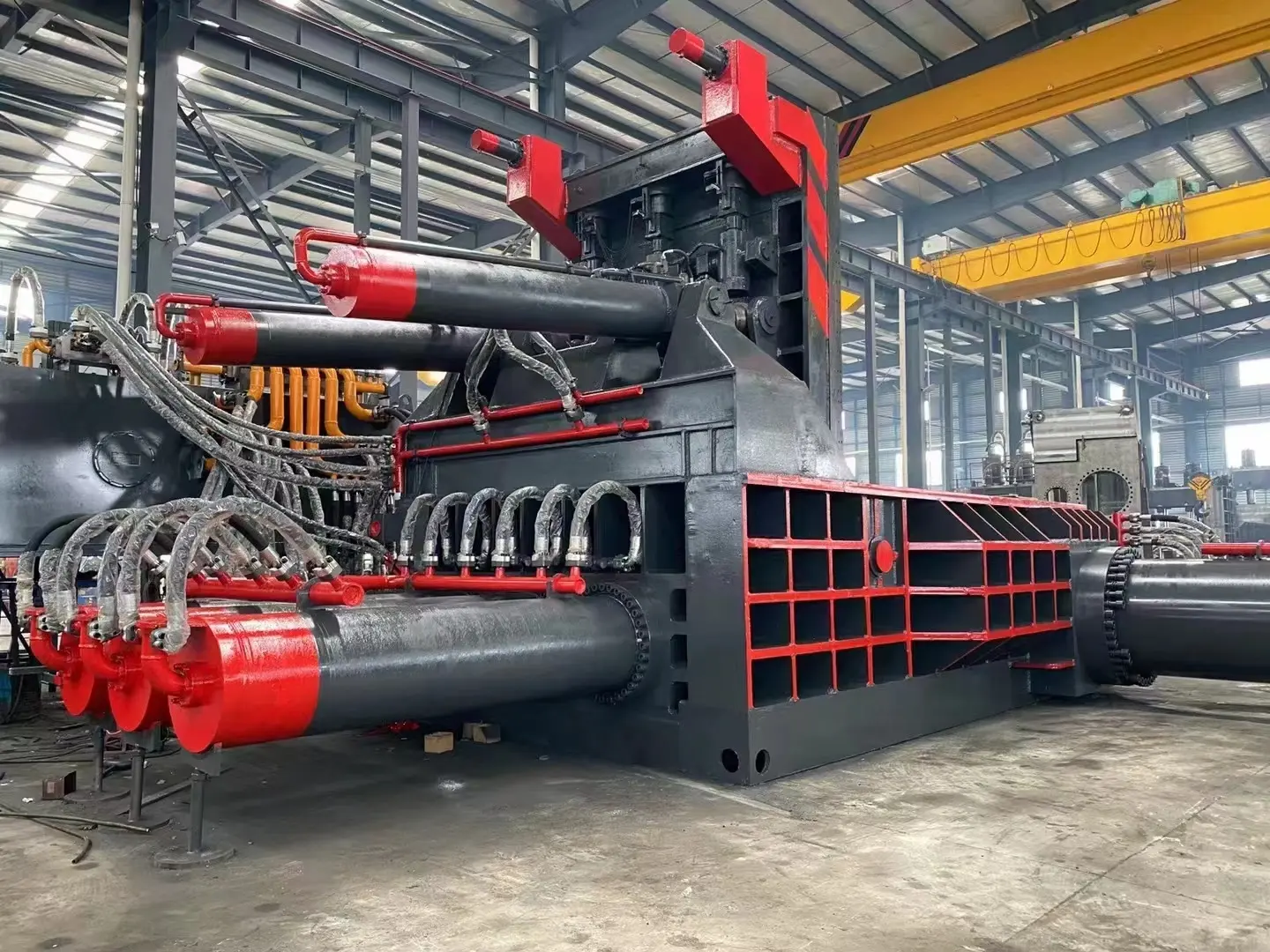

The strength of mobile shears lies in their adaptability. They can be mounted on various types of heavy equipment, including excavators, Material Handlers, and specialized recycling machinery. This mounting flexibility allows operators to deliver cutting power directly where it’s needed most, whether at a bustling scrap yard, an active demolition site, or a metal recycling facility.

Mobile shears operate through a powerful hydraulic system that drives their upper and lower jaws. These jaws feature hardened steel cutting blades specifically designed to slice through various metals. The upper jaw moves against the stationary lower jaw, creating a scissor-like action that provides maximum cutting force precisely where needed.

When processing scrap metal, the operator positions the shear at the desired cutting point. The jaws open wide—typically between 22 and 32 inches, depending on the model—allowing them to grasp large pieces of steel, rebar, or other metals. Once the material is secured, the hydraulic system activates, driving the blades together with an impressive force ranging from 600 to over 1,000 tons of cutting pressure.