How Is Metal Recycled

Scrap Metal collection

The first step of the collection process starts with you. Whether it's at work or at home, scrap metal is all around you. Allocate containers in your garage or facility specifically for the collection of your scrap. Make sure that the containers you are using can safely hold the metal. If there is a lot of scrap metal at your enterprise, Translom will assist in organizing the transportation of scrap metal.

Sorting of scrap metal

As soon as the company picks up the scrap metal from you, it will start the sorting process. Although scrap may have been pre-sorted, this is done to ensure quality.

How Metal Is Recycled, Scrap

Metal Processing First, the metals are separated from other materials. The plastic is removed from the wires and the metal parts are removed from the objects. Then, with the help of magnets, ferrous and non-ferrous metals are separated.

Sorting by Type and Purity

After that, the metals are sorted by type. This is done taking into account the color and weight of the metals. For example, copper is yellowish-red, while aluminum is silver.

Finally, metals are separated by purity. This means whether the metal is pure or impure. The automated operation includes magnets and sensors such as infrared scanning and X-rays.

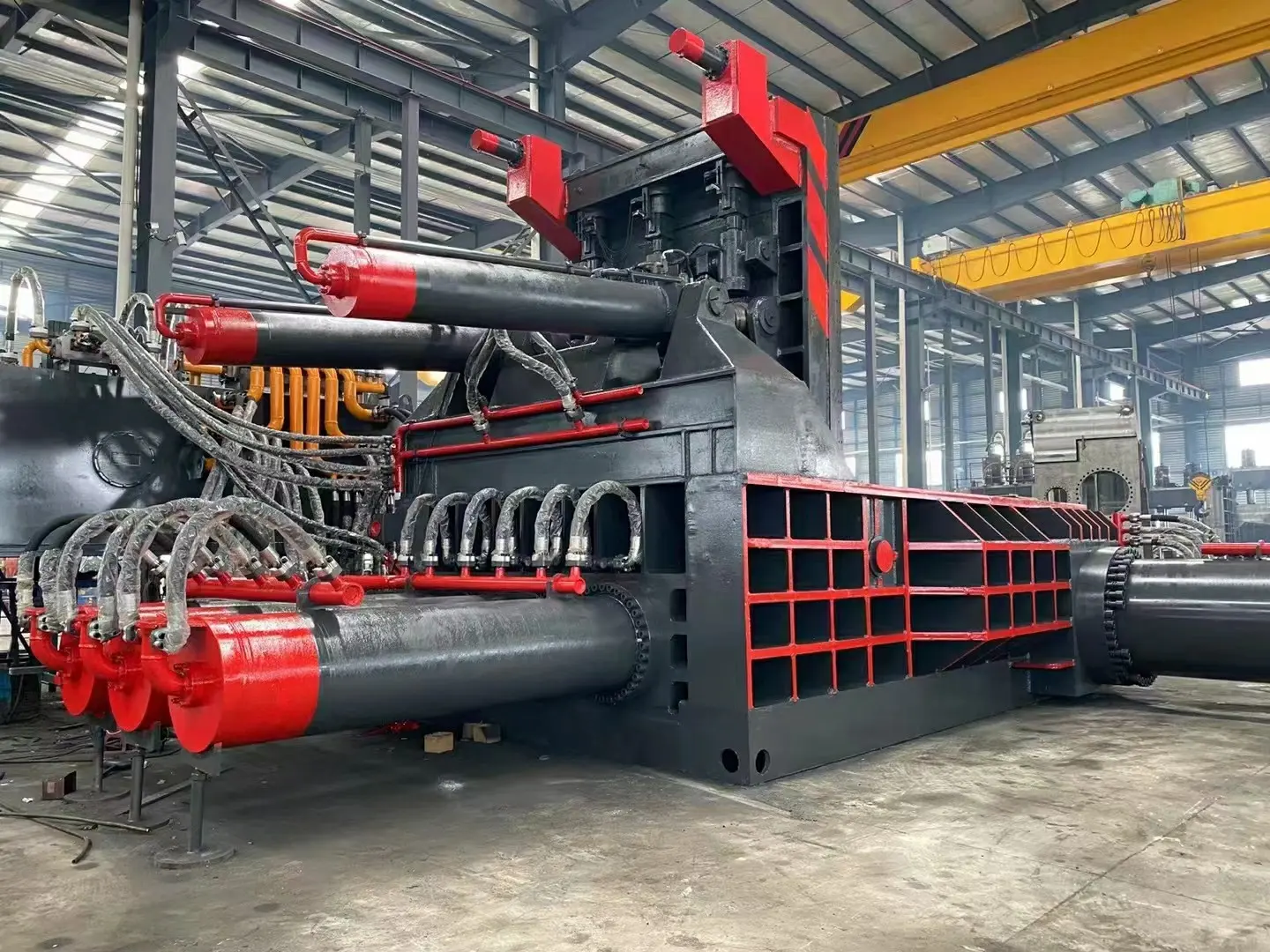

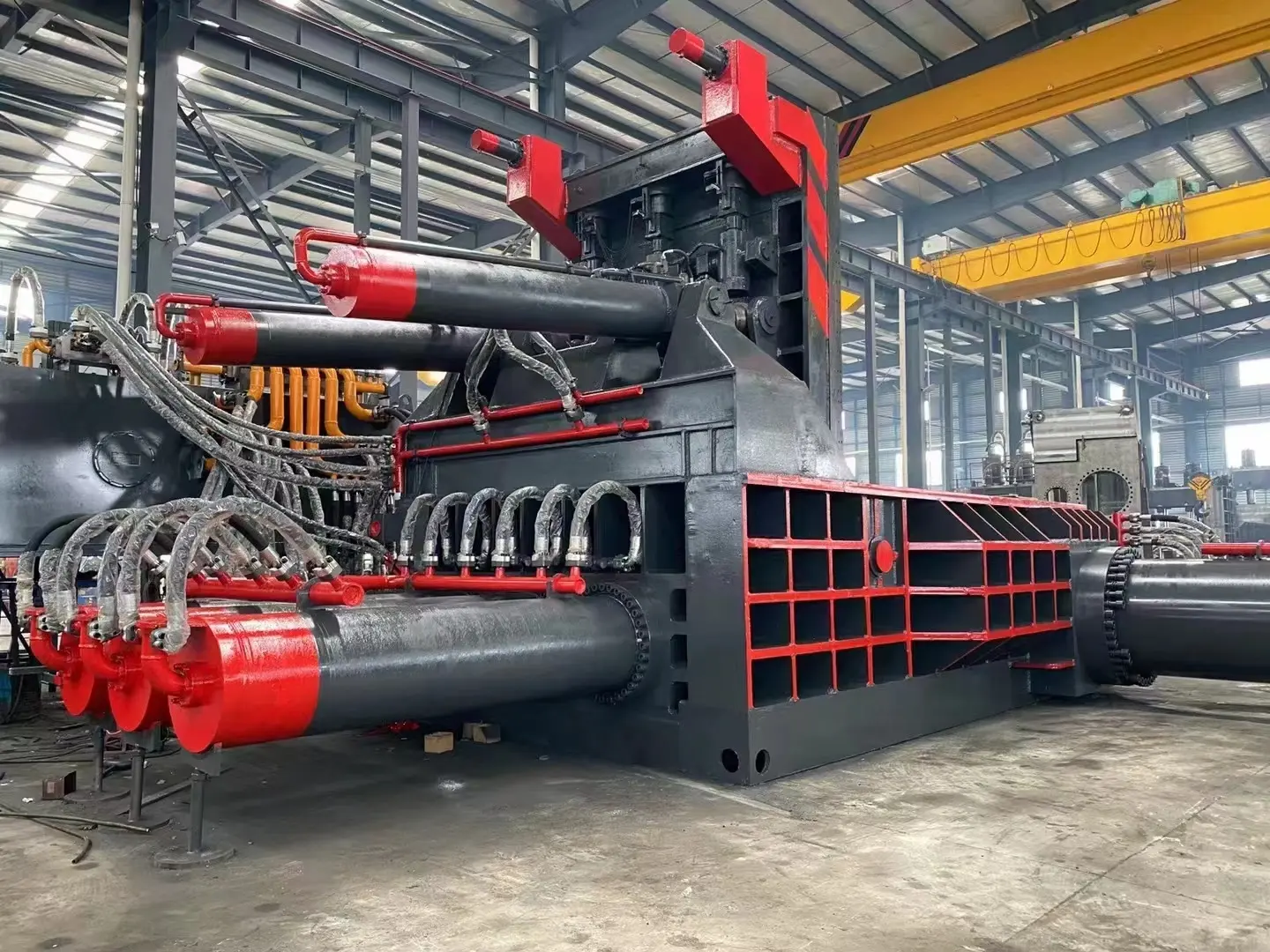

Metal Processing

This brings us to the next stage of scrap Metal Recycling. During this process, the metals are first compacted and compressed together to take up less space. They are then cut into smaller pieces using hydraulic equipment.

It is then crushed into even smaller pieces by passing it through hammer mills. Metal grinding makes the melting process easier because when the pieces are smaller, a greater surface-to-volume ratio is created.

Smelting of scrap metal

Metal melting takes place in furnaces. The furnace is tuned to each specific metal because each requires a different level of heat. The size of the metal and the furnace affect the time it takes to melt. It can range from a few minutes to several hours. Although this process requires the use of energy, it is much less than is required to produce new metals.

Metal Cleaning

To ensure quality, the metals are cleaned of any impurities. One of the purification methods is electrolysis. In this process, an electric current is passed through the metal and the pure metal is deposited on the cathode and the impure metal is dissolved.

Scrap metal recycling

Impure metal is the anode, while pure metal is the cathode. Soluble metal salt is an electrolyte. These impurities collect under the anode, also known as anode slurry. On the other hand, other metals just need to pass under a strong magnet that can separate the metals.

Hardening

This is the last process that the metal goes through before being shipped. First, chemicals are added to the molten metal to create the desired properties.

The molten metals are then passed through a conveyor belt that takes them to a cooling chamber to solidify.

Some metals are melted into sheets and others into compacted blocks in a process called baling. This is done in order to facilitate the production of new products by manufacturers.

Transportation

Now that the metals have been refined and hardened, it's time to send the metals to manufacturing plants. Manufacturers can then make entirely new products from these metals. New products are sold to consumers, and then the process begins again.

Why More Metal Recycling Is Needed

Almost any type of metal can be recycled. However, the current metal recycling rate of 30% is too low. Both businesses and people can benefit from recycling their scrap metal.

Financial Benefits

There is a clear financial incentive for metal recycling. Scrap metal collectors who collect scrap metal and bring it to a recycling company can make money. The same applies to enterprises.

In addition, recycling reduces costs in the production process. Using recycled metals is much cheaper than making new products using virgin raw materials.

In addition to saving money, metal recycling also allows manufacturing plants to reduce their overall production costs. These savings are then passed on to consumers.

Another great way it benefits the economy is by creating a need for new jobs.

Environmental Benefits

Of course, metal recycling has an important environmental impact. Metal recycling allows us to conserve natural resources. Also, much less energy is spent during its processing than when using primary ore to obtain new metals. In addition, much less carbon dioxide and other harmful gases are emitted. Recycling scrap metal provides significant energy savings.