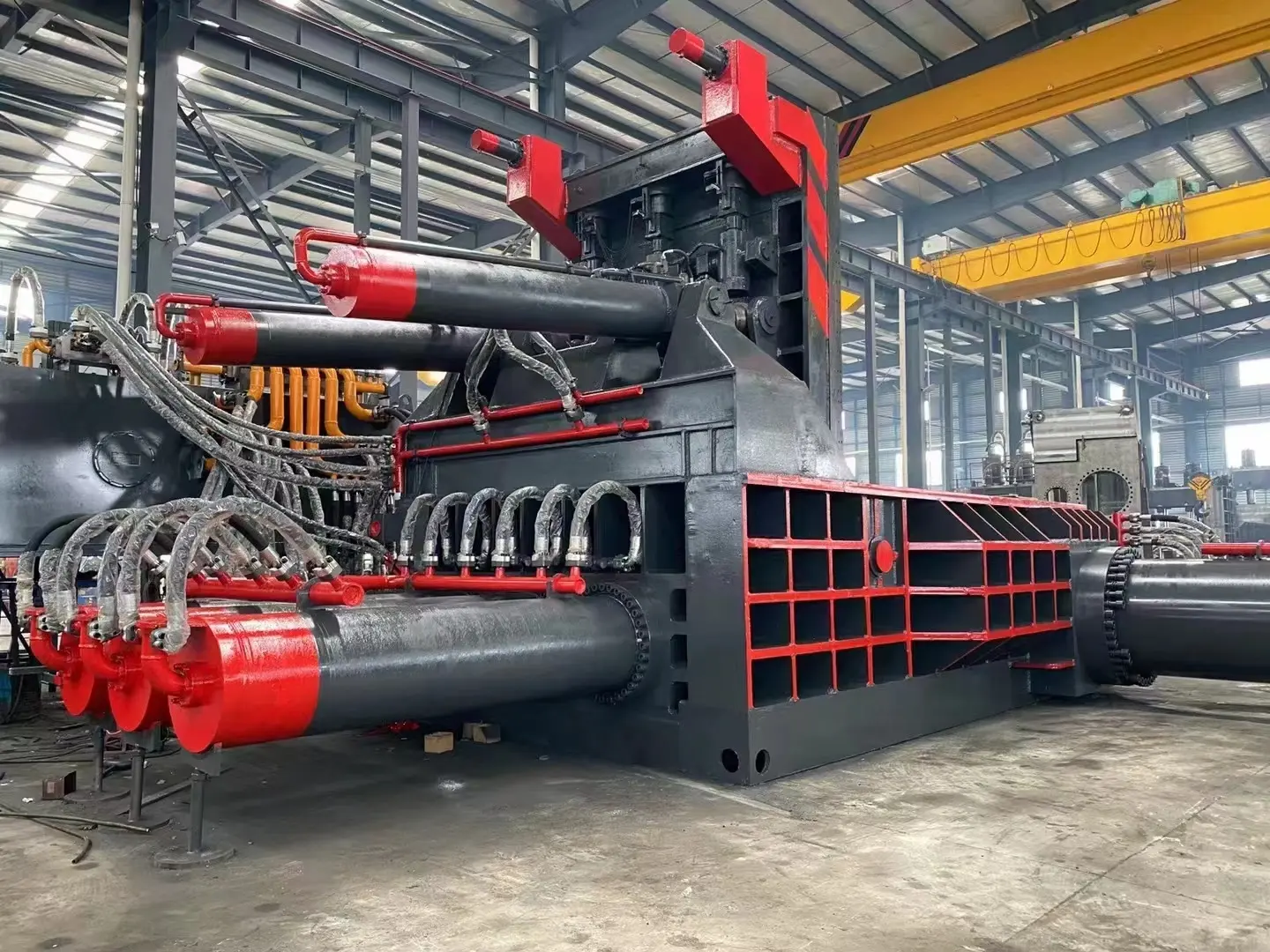

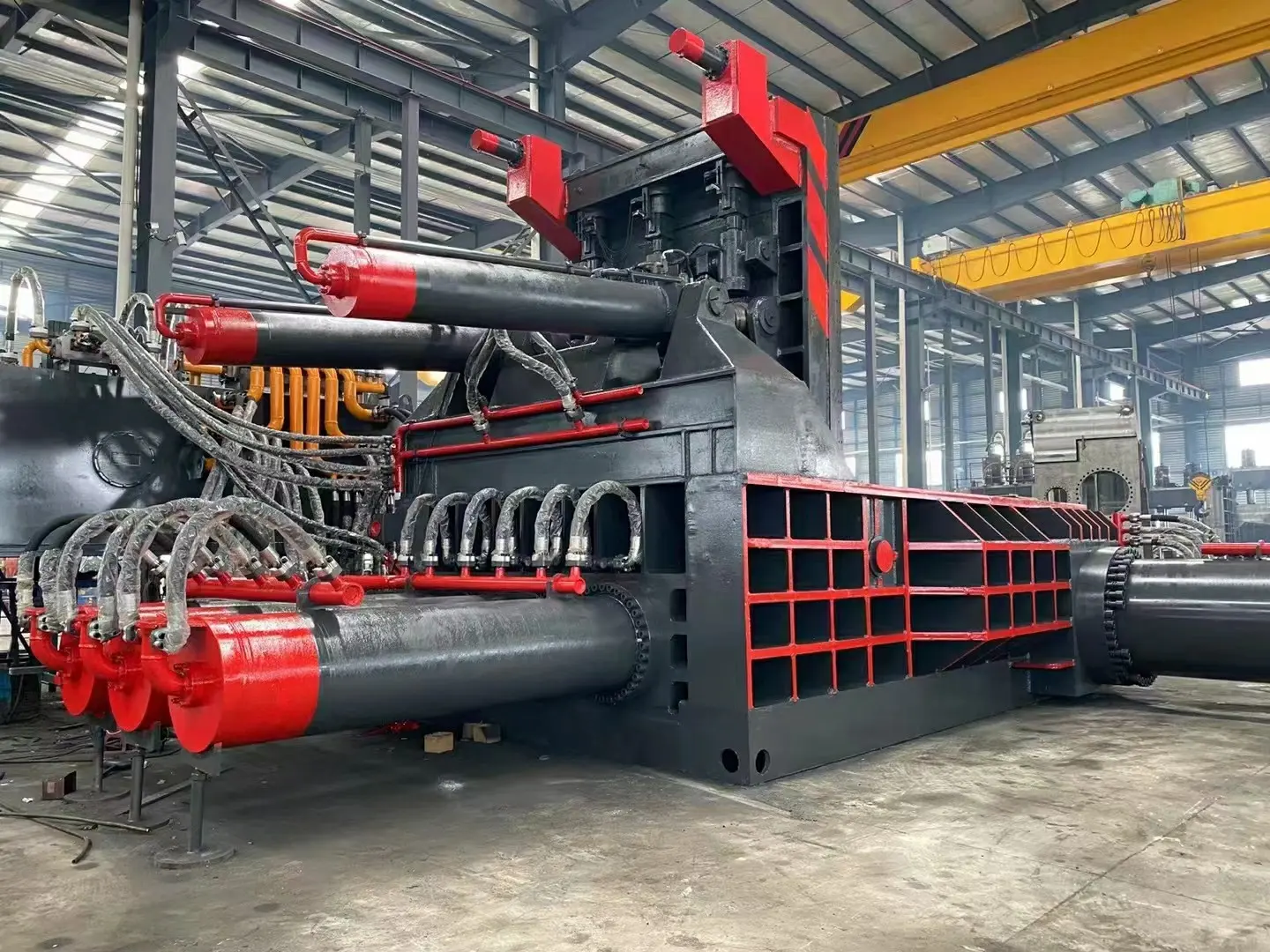

Hydraulic Scrap Metal Baler

A Scrap Metal Baler is an electromechanical product primarily composed of mechanical, control, feeding, and power systems. The entire baling cycle consists of auxiliary times for compression, retraction, lifting, rotating, bale ejection upward, bale ejection downward, and bale receiving.

Scrap paper balers on the market are mainly divided into horizontal and vertical types. Vertical scrap paper balers are relatively compact due to their smaller bale size and lower efficiency.

In contrast, horizontal scrap paper balers are significantly larger than vertical ones. However, they offer greater compression force, produce larger bales, achieve higher output efficiency, and are easier to automate. Consequently, most scrap paper balers adopt the horizontal configuration.

Horizontal scrap paper balers facilitate automation, enhancing overall baling efficiency and reducing labor costs.

Key Components & Operation:

Vertical Scrap Paper Baler:

- Wire Guide Frame: Comprises four sets of wire guiding devices mounted on a frame. The entire guide frame is suspended from a central shaft on the compression frame and moves horizontally relative to the compression frame, driven by a hydraulic motor.

- Compression Frame: A welded structure with wheels at the bottom. Hydraulic cylinders propel it horizontally along the main rails.

- Lifting Platform: Primarily constructed from two bolted horizontal beams. Two hydraulic cylinders drive it to move vertically up and down.

Scrap Metal Baler:

- Compression Frame: Similar in structure to the scrap paper baler's frame, but equipped with four baling heads and one set of wire feeding device.

- Baling Heads (x4): The most structurally complex components of the entire machine with numerous interlocked movements. All four baling heads on a scrap metal baler are identical and interchangeable.

- Wire Feeding Device (x4 sets): One set per baling head. Each set includes a baling wire conveying device and a baling wire tensioning/reverse pulling device.

Common Elements:

Main Rail Base (Vertical Baler): Primarily consists of two rails fitted with wear-resistant steel tracks on top. The compression frame wheels run along the outside of these tracks. The hydraulic cylinder driving the compression frame is positioned here.

Hydraulic Power Unit: A complete hydraulic station is essential, in addition to the mechanical components. As evident from the above description, the various movements in scrap metal balers are accomplished using fluid power (hydraulics).

Important Considerations When Using Scrap Metal Balers:

- Continuous Quality Monitoring: During operation, continuously inspect product quality and make immediate adjustments if any issues arise.

- Safe Shutdown for Issues: If equipment malfunctions or product quality becomes unacceptable, immediately shut down the baler to resolve the problem. Prohibited: Troubleshooting while the machine is running to prevent accidents.

- Operator Cleanliness: Operators must maintain cleanliness when handling the machine and equipment.

- Touchscreen Operation: Operators may only use the machine's touchscreen with clean fingers. Prohibited: Tapping or striking the touchscreen with fingertips, fingernails, or any hard objects, as improper operation may damage the screen.

- Safe Debugging Procedures: When debugging the machine or adjusting parameters (bag making quality, packaging quality, filling effect, bag display, packaging bags), only use the manual switch for adjustments. Prohibited: Performing such debugging while the machine is running to prevent safety accidents.