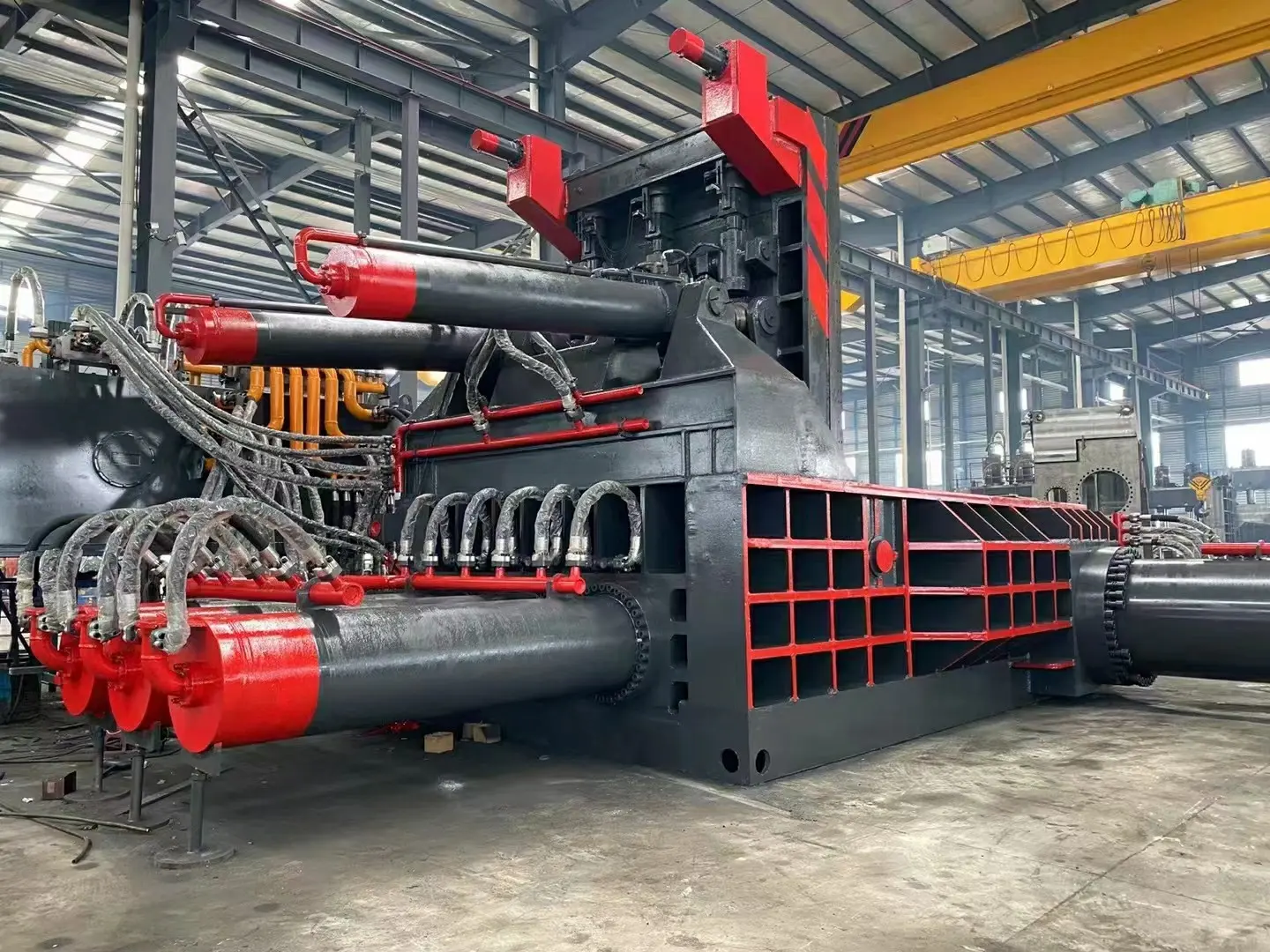

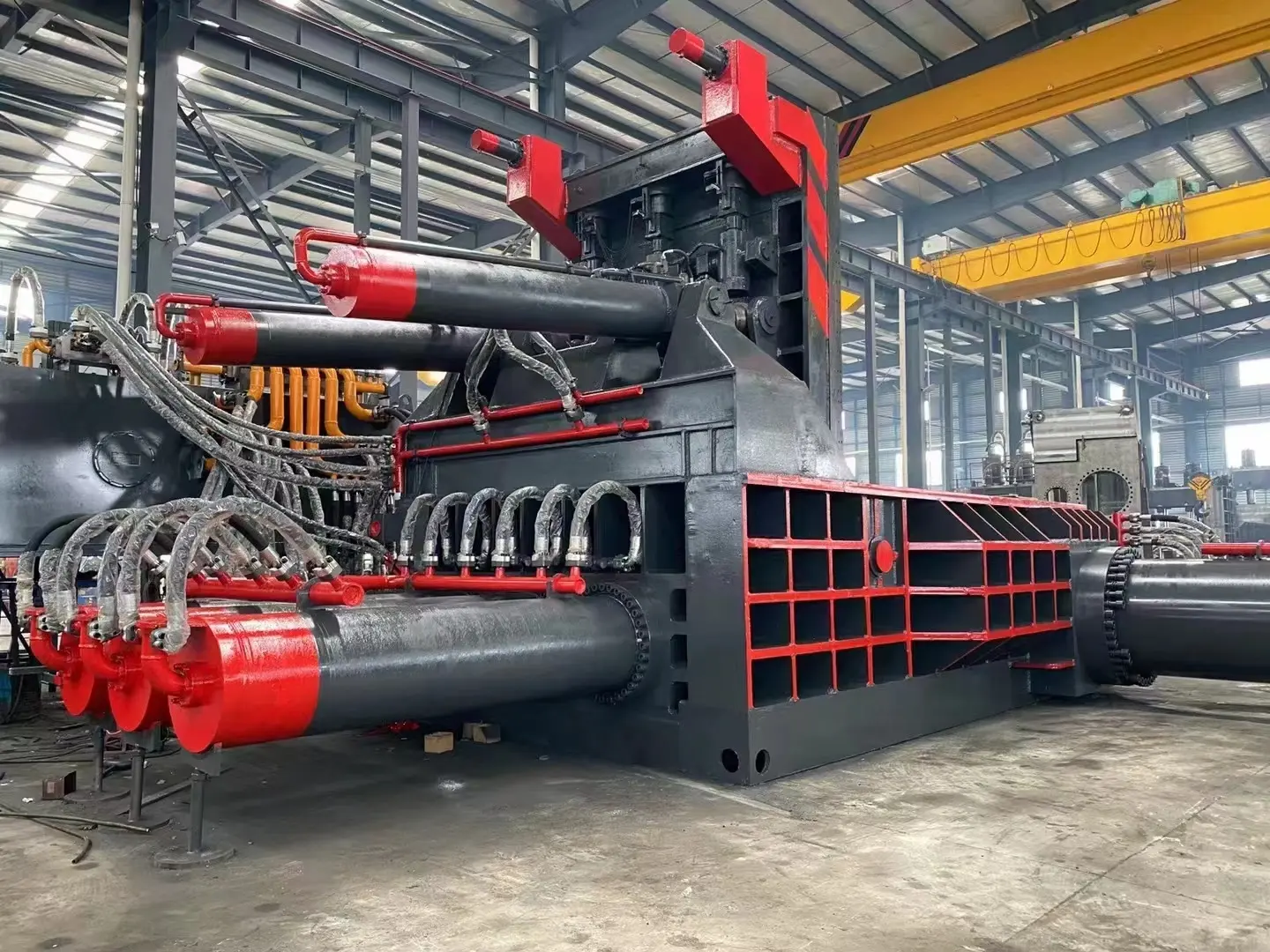

Scrap Metal Baler Technical Overview

The Scrap Metal Baler represents an integrated mechatronic system comprising four primary subsystems:mechanical, control, feeding, and power systems. Its operational cycle involves multiple phases, including compression, return stroke, container lifting, container rotation, upward/lower bale ejection, and bale reception.

Market-available scrap metal balers are predominantly categorized into vertical and horizontal configurations. Vertical balers feature more compact dimensions corresponding to their smaller bale size, though this design yields relatively lower operational efficiency. In contrast, horizontal balers offer distinct advantages:

1. Greater compression force capacity

2. Larger resultant bale dimensions

3. Enhanced production throughput

4. Superior automation compatibility

These performance characteristics explain the industry's predominant adoption of horizontal configurations. The automation-ready design of horizontal balers significantly improves overall processing efficiency while reducing labor requirements.

Structural Components:

1. Press Frame: Utilizes a conventional press-frame structural design

2. Baling Head (Hydraulic System): The most structurally complex assembly, featuring multiple interlocking mechanical actions

Functional Definition:

A scrap metal baler is an industrial compaction device designed to process waste metals into dense, transportable bales for optimized storage, logistics, and recycling operations.