0102030405

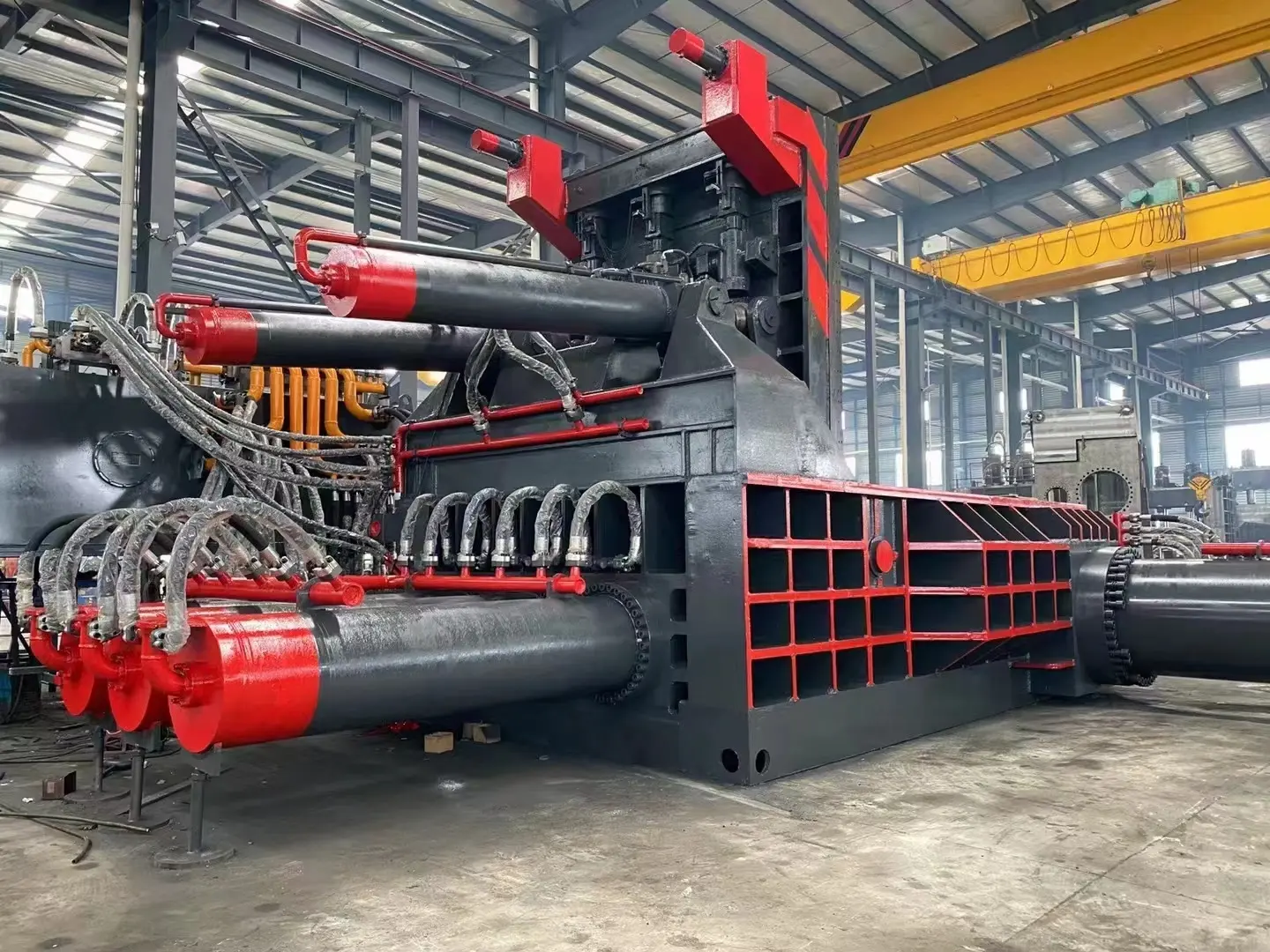

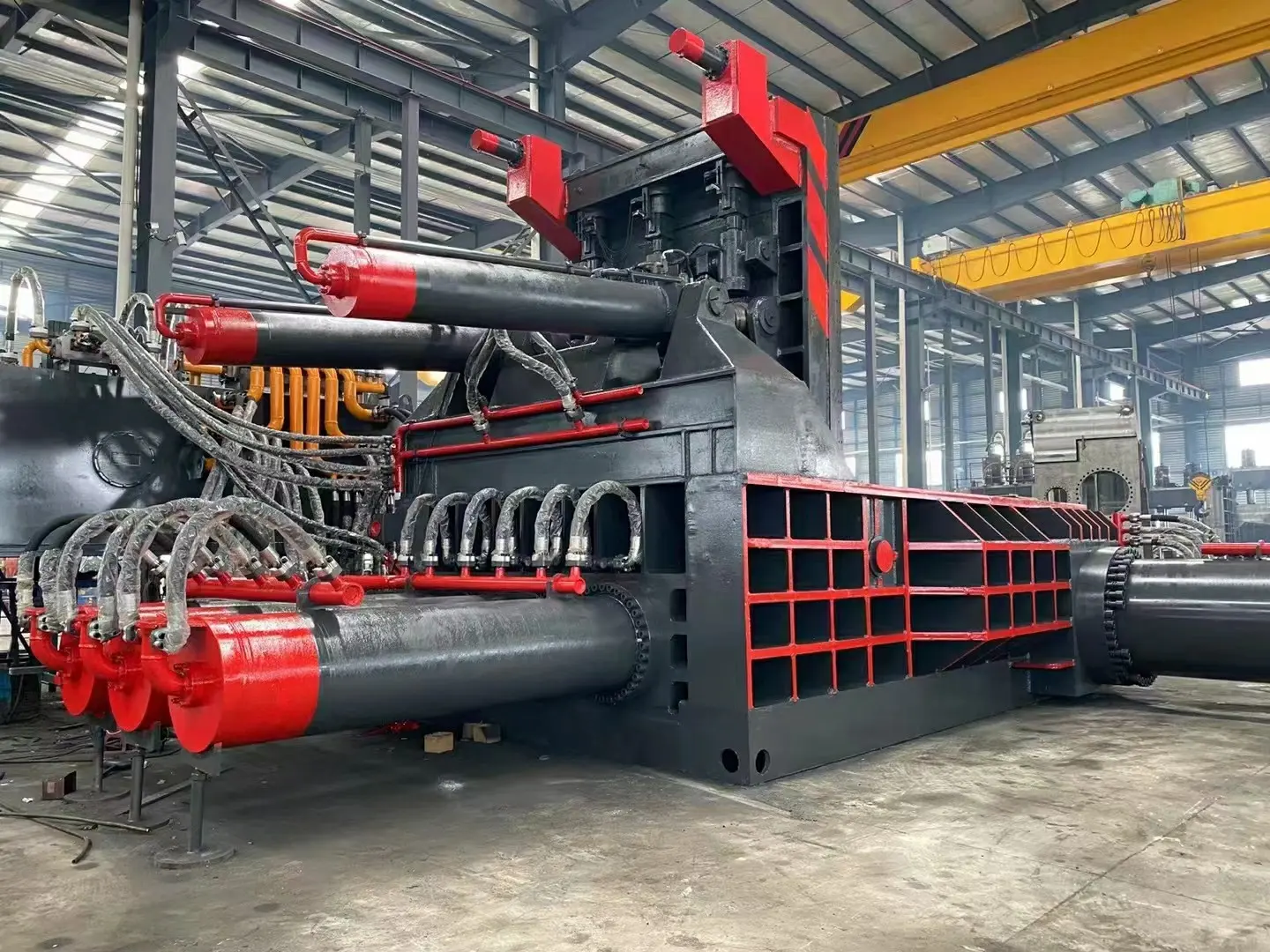

Scrap Metal Baler: You Need to Know

2025-12-03

Scrap Metal Balers, also known as metal scrap baling machines or compactors, play a crucial role in the metal recycling industry by transforming loose metal scraps into manageable, dense bales.

How Does a Scrap Metal Baler Work?

A scrap metal baler compresses loose metal into dense, uniform bales for efficient handling. The process starts with loading scrap into a chamber. A powerful hydraulic system then activates, driving a ram to apply extreme pressure and compact the metal into a solid block. The entire cycle—controlled for safety and consistency—is completed in minutes, readying the bale for transport and streamlining recycling operations.

Why Choose Our Baler?

- Energy-Saving Servo Motor System: Unlike standard motors, our servo-driven system is significantly more energy-efficient. While the initial investment is higher, it can save you tens of thousands of RMB in electricity costs per year, offering a faster ROI and lower environmental impact. This is ideal for clients focused on stable, long-term efficiency and total cost of ownership.

- Dual-Hydraulic Cylinder Design: Compared to single-cylinder balers, our dual-cylinder system delivers higher efficiency and faster cycling. A single cylinder would require a stroke length at least twice as long, resulting in slower operation.

- Flexible Control System: We offer a choice between Automatic and Manual control modes. While the automatic system (recommended for higher-power models) has a higher upfront cost, it optimizes operation. Manual mode provides a cost-effective solution for lower-power requirements.

- Premium Wear Plates: Key wear components can be lined with imported Swedish HARDOX steel, known for exceptional hardness and durability. This extends the machine's service life dramatically and reduces long-term maintenance costs.

- Top-Tier Core Components: We use first-class, nationally recognized brands for critical parts like the hydraulic pump, motor, and valve blocks. This ensures reliable performance, consistent quality, and minimal downtime.

In short, we build for reliability, efficiency, and your bottom line.